While a high-performance measuring machine is a prerequisite for staying competitive, many quality managers are not achieving maximum efficiency and quality with their coordinate measuring machines (CMMs). One way to optimize the overall performance of CMMs is by integrating the right styli and accessories, the ones designed for and of the same caliber as the inspection systems. They can help deliver the results a measuring room is trying to achieve.

The initial investment in a CMM is just the first step. It may have been configured to measure a specific part or solve a particular need. Later, as the full potential of the system is learned, the quality manager is faced with applying that knowledge to new and greater inspection challenges. That’s when they need to consider the styli and accessories designed by the original equipment manufacturer (OEM).

The OEM brings the expertise of knowing how all the components work together for the best solution. It’s simple to maintain efficiency in the measuring room with easier access to application expertise to optimize the system for accuracy and efficiency.

No Room for Error

What challenges could arise without the right additions to your quality area? Inspections of complicated geometries may require detailed stylus configurations.

As the configurability of your stylus system impacts your machine throughput and measuring accuracy, finding, creating and implementing the right accessories is critical. In addition, the right stylus sphere and a thermally stable stylus system can have significant impact on the most important CMM capabilities: measurement accuracy and repeatability.

To create your ideal measurement room, you need an OEM that understands and maintains machine capabilities and provides the right accessories and tools that can be configured to continually meet your quality program needs.

The Stylus System Creator (SSC) can speed up a quality room’s measuring time.

Making the Right Hardware Choices

Purchasing high-quality accessories engineered for your machine from the OEM can be one of the most important conditions for expediting and optimizing the measuring process. It’s important that the construction of your accessories match up with your application for best results. Find a manufacturer who can illustrate the value of different stylus tip and extension materials, various stylus shapes, and tools to improve efficiency.

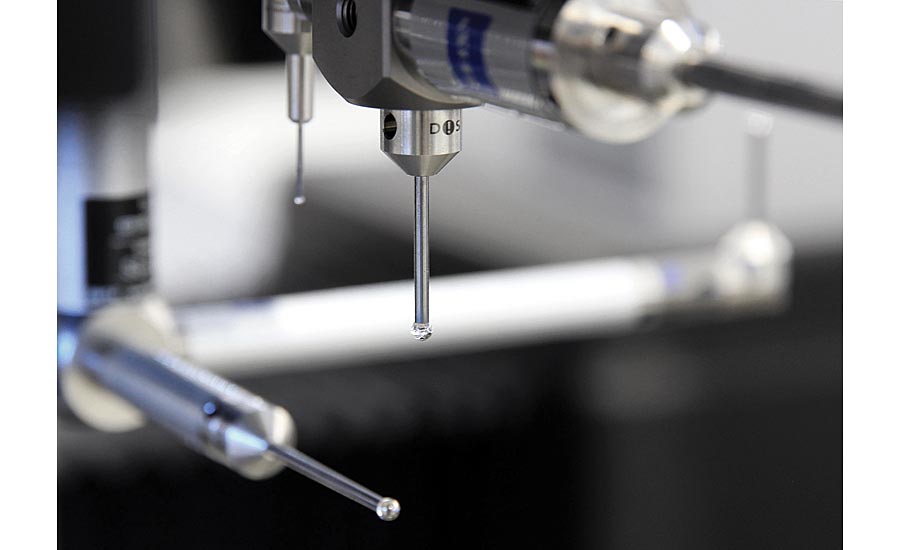

Let’s start with the material typically used for the stylus tips. Most applications default to ruby tips, a good material that offers high accuracy. But there are some things to be aware of. Scanning hard workpieces wears down the surface of the ruby sphere, and scanning soft workpieces creates build-up on the sphere as the tip strips away small amounts of material over the measurement run. Fortunately, quality managers have alternative materials for tips—such as silicon nitride, tungsten carbide and even diamond.

Diamond tips of course are a lot more robust than their ruby tip counterparts. Diamonds have less wear than ruby tips and, consequently, no need to check for wear. There is no need to inspect and clean the stylus tips because no material remains stuck to the sphere’s surface. There are stylus tips made of solid diamond and diamond-coated spheres, or a monolithic diamond coated design. Diamond-coated monolithic tips have a one-piece design.

Secondly, let’s look at the parts connected to that tip. Ideally, you should choose the shortest practical stylus length for your probing application as the more deflection or bending of a stylus the higher the chance of error and reduced accuracy.

This stylus tip is made of solid diamond and diamond-coated spheres.

If an application requires longer extensions, weight can become an issue. The lighter and more rigid the stylus extensions are, the faster the operator can measure without negatively impacting the precision of the system through bending or centrifugal forces. Carbon fiber is the best option for stylus extensions as it is lightweight, has high flexural strength and, because of its thermal stability, eclipses other materials like aluminum, stainless steel, steel, titanium and ceramic.

It’s also important to note there are several stylus tip shapes to consider, depending on your measurement application. Ball tips are the most versatile, as they exhibit the same probing behavior in all scanning directions. While being a bit more challenging to calibrate, disk tips are ideal to measure inner and outer cylinders of boreholes and undercuts, and to localize deep grooves and large boreholes. Cylinder tips are an excellent option for 2D measurements, especially for narrow workpieces like thin sheets. To achieve optimal measurements with a cylinder tip, it is important to ensure that the stylus axis is mechanically and precisely aligned with the feature axis. Like cylinder tips in application, spherical cylinder tips are helpful when trying to determine surface flatness. Half-sphere tips are well-suited for inspecting undercuts and help optimize weight when large spheres are required to complete the required measurement. Finally, star tips are capable of probing from any direction and are frequently used to measure workpiece side surfaces.

Proper configuration

Optimizing the proper lengths, angles, and stylus arrangement is important for accuracy, performance and repeatability. Both hardware and software can help in this area. You can minimize the number of stylus system changes when running your measuring program, which saves time and increases throughput.

From a hardware perspective, an angle set-up device for styli can help. The stylus set-up devices can set more angles in the system accurately compared to tools that align the cube to the adapter plate, or a protractor.

ZEISS Webshop allows customers to order styli, machine accessories or measuring room equipment.

Having a comprehensive metrology software solution can be a productivity booster for a quality manager’s program. To take full advantage of your metrology systems, look for software that:

- Allows virtual creation and testing of probe tooling

- Configures the required stylus systems

- Integrates fixtures and entire changer racks into simulations

- Generates travel paths automatically to eliminate possible collisions

Conclusion

If you want to achieve the highest quality and maximum productivity in your inspection room, it’s critical to optimize your measurement machines and quality program with the right tools for your applications. By purchasing all metrology hardware and software components directly from one manufacturer, you’re guaranteed optimal measurement accuracy and repeatability through consistent in-house expertise. This breadth of knowledge and experience will help your quality department find the right solutions for whatever measurement and inspection challenges lie ahead. Q