Home » Keywords: » specifications

Items Tagged with 'specifications'

ARTICLES

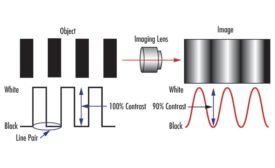

In the past, cameras were once the limiting component for performance in and imaging system. Today, lenses have become the critical component in many applications.

Read More

Keeping Up Standards in Machine Vision

The use of industrial vision as part of Industry 4.0 and smart factories has been discussed extensively in recent years, but requires machines to speak the same language.

November 15, 2018

How Proper Specification of Load Cell Sensors Can Improve Force Measurement

Accuracy is only one of many characteristics that should be examined before selecting a sensor for an application.

November 8, 2018

The Ideal Stylus System

Choosing the right components and construction impacts your measuring result

September 1, 2018

The Effective System Integrator

Risks are inherent in any engineering activity such as system integration.

July 1, 2017

Get our new eMagazine delivered to your inbox every month.

Stay in the know with Quality’s comprehensive coverage of the manufacturing and metrology industries.

SIGN UP TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing