“I was stunned to learn that the Titan submersible had supposedly not undergone any NDT testing,” said Greg Weaver, president of WeaverNDT, and an NDT professional with nearly 25 years of experience. “It was even more of a surprise to find out that company employees allegedly had concerns over the lack of safety, but that the Titan still proceeded to dive to deep depths with passengers onboard.”

Chuck Hellier, vice president of NDT Classroom Inc., added, “It is inconceivable that a critical submersible such as the Titan was not subjected to the most extensive nondestructive tests available.”

Both Weaver and Hellier cited ultrasonic testing and radiography inspections that could have potentially helped avoid the Titan’s fate. “These methods are used to ensure that the submersible is structurally sound and that it is free of any relevant defects,” said Weaver.

NDT

Related Articles

Both also suggested the new design and new carbon fiber hull material provided even greater reason for extensive testing. Weaver noted that carbon fiber has been an accepted material for manufacturing in many industries for several years and known NDT methods are being applied to its inspection.

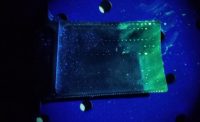

“The Boeing Dreamliner is a great example where carbon fiber is being used for critical components. The Dreamliner’s fuselage structure is made of carbon fiber, and it is inspected using the NDT method of ultrasonic. This method introduces ultrasonic waves into the carbon fiber and the result is a C-scan image of the inspected area. These are usually very easy images to interpret, and the results are provided quite quickly,” said Weaver. “This type of inspection information is relatively easy to find. It requires only a quick internet search to discover the companies that provide this equipment and services.”

Even a new design and standard hull materials would have come with specific NDT inspection call outs, said Weaver. “They require these inspections and would not be skipped under any circumstance where a human life would be at risk,” he said.

Hellier mentioned the US Navy uses both UT/PAUT and RT for their submarines and these methods should have been used as a minimum [on the Titan], “to provide the utmost assurance that no critical discontinuities were present.”

“With the Titan, we have a new design, but also the use of carbon fiber as a new hull material,” said Weaver. “So, why didn’t the same NDT methods get used?”

Hellier also acknowledged David Lochridge. “I applaud David Lochridge, who was fired by the company after he expressed concern about the safety of the Titan submersible due to the lack of appropriate nondestructive tests,” he said. “I believe the implosion of the Titan may have been averted if the proper NDT examinations had been applied using qualified procedures and personnel.”

Both Hellier and Weaver recognized that NDT inspection is no guarantee. “Of course, there is no guarantee that every flaw can be detected with even the latest techniques due to the many variables such as technique sensitivity, flaw orientation and size, examiner qualifications and procedure used,” said Hellier.

Both also strictly acknowledged that they are observers, much like the rest of us. “With no firsthand knowledge of the manufacturing and testing program of the Titan, the statements made above are all based on secondhand reporting since the horrible incident occurred,” said Weaver.