Surface finish is not just a mundane aspect of everyday objects; it holds tremendous importance in a wide range of applications. From optimizing household paper products to manufacturing high-performance pickleball paddles and even ensuring the comfort and efficacy of surgical implants, surface finish measurement is critical. This article will highlight the unique ways surface measurement is utilized throughout various industries.

First, here are just a few reasons why surface finish is critical:

Performance and Functionality: Surface structure can significantly impact the performance and functionality of a component or product. For example, precise surface finishes are critical for parts that must fit together with tight tolerances, such as sealing surfaces, mating surfaces, or moving parts in machinery. The optimal surface finish can reduce friction, wear, and corrosion, ultimately improving the performance and longevity of the manufactured product.

Safety: Surface finish is also critical for safety in certain applications. For instance, components with specific surface finishes may enhance grip in industrial environments, reducing the risk of slippage or accidents. Surface finishes can also help with electrical insulation or heat dissipation, ensuring electrical and electronic equipment safety.

Disinfection: In applications where cleanliness is essential, such as medical equipment, food processing machinery, or pharmaceutical devices, surface finish plays a key role. For example, smooth, non-porous finishes are easier to clean, sanitize, and sterilize, preventing the buildup of contaminants, bacteria, or other harmful substances.

Appearance: Surface finish can play a crucial role in determining the visual appeal of a product. A high-quality surface finish enhances the overall aesthetics of the item. Depending on the desired outcome, it can give a product a polished, smooth, or textured look.

Exploring The Wide Range Of Applications For Surface Finish Measurement

With new processes and materials coupled with a deeper understanding of coating, bonding, lubrication, and friction, surfaces also have an increasingly technical function. In any of these cases, engineered surfaces must meet specific requirements for quality purposes, so the ability to precisely measure surface finish is crucial.

Household Paper Products: There is a surprising amount of science behind making household paper products such as toilet tissue and paper towels that optimize characteristics including smoothness or absorbency. Surface finish and texture play a big part in this. A proper surface finish measurement can help optimize these key product attributes by determining the ideal combination of smoothness and porosity. This ensures that household paper products efficiently absorb liquids while maintaining a soft and gentle feel.

Additionally, surface finish measurement helps determine performance characteristics. For example, surface finish affects strength and tear resistance. By measuring and controlling these parameters, manufacturers can produce household paper products that are strong and durable. Surface finish measurement further ensures consistent quality in paper products. Manufacturers can ensure that the final products meet desired specifications by measuring the roughness, smoothness, or texture.

Manufacturing High-Performance, Tournament Legal Pickleball Paddles: Pickleball is currently one of the fastest-growing sports in America, with an estimated 36.5 million players in 2022. The surface finish of a pickleball paddle is critical as it directly impacts player performance. For example, a consistent surface finish allows for better ball control, accuracy, and spin generation.

Surface finish measurement is necessary to comply with regulatory standards. The Professional Pickleball Association (PPA) mandates that amateur or professional paddles used at any PPA event must be on the organization’s approved equipment list. This specifically includes surface roughness measurement. The organization states that a roughness test must be administered on the paddle surface for the equipment to be tournament legal.

Surface finish also affects the paddle’s durability and wear resistance. By measuring the surface finish, manufacturers can ensure that the paddle can withstand repeated impacts, resist scratches, and maintain its performance over time.

Golf Club Specifications: Similar to pickleball, golf clubs must adhere to rules and regulations set by governing bodies such as the United States Golf Association (USGA). Surface finish measurement is necessary to ensure compliance with these regulations, which include limits on groove geometry, roughness, and other surface characteristics. For example, USGA mandates that the face of the club must conform to specific surface roughness specifications, while the width of each groove may not exceed a specified inch measurement.

The interaction between the golf ball and the club face is also critical in determining distance, accuracy, and feel, and surface finish plays a role in this interaction. By measuring the surface finish characteristics, such as roughness or smoothness, manufacturers can tailor the club face to provide the desired level of friction or reduced spin for specific shots, resulting in improved control and shot consistency. Surface finish also affects the club’s overall performance as texture, polish, and more can influence factors such as ball spin, launch angle, and forgiveness.

Measuring Rock/Asphalt to Optimize Tire Performance: Surface texture and roughness data play a pivotal role in determining the traction and grip of tires on rock or asphalt surfaces. The analysis of surface finish enables engineers to gain valuable insights into the influence of these factors to help optimize tire designs to provide an ideal balance of grip and stability, ultimately enhancing the tire’s performance in various road conditions.

In addition to traction and grip, the impact of road surface on tire wear is significant. Irregular or rough surfaces can lead to accelerated tire wear and an increased risk of tread damage. By thoroughly understanding the effects of different road surfaces, manufacturers can develop tire designs that mitigate these issues, extending the lifespan, reducing maintenance costs, and enhancing durability.

Acquiring topography data provided by surface measurement technologies is critical to this process. Rock and asphalt surfaces are typically measured on test tracks to analyze the impact on tire performance. Advanced computer modeling and simulation techniques are applied to understand the behavior of rubber compounds under various surface conditions. By correlating the results with surface measurements, engineers can scrutinize the impact of different surfaces on tire performance, enabling them to optimize designs. This comprehensive approach ensures that the tire performs optimally based on the specific characteristics of a typical road surface.

Measuring Floors to Reduce Slip Hazards: Accidents caused by slips and falls can result in injuries, legal liabilities, and financial losses. Property owners can proactively manage surface finishes, reduce slip hazards, and mitigate the risk of accidents. This not only safeguards the well-being of occupants but also leads to potential cost savings associated with injury claims, legal disputes, and insurance premiums.

With roughness measurements, engineers can more thoroughly evaluate the slip potential of a floor surface. This information is essential in identifying high-risk areas and implementing appropriate measures to reduce potential hazards. Furthermore, different flooring materials and finishes exhibit varying slip resistance properties. Therefore, surface finish measurement enables building designers and facility managers to make more informed decisions about selecting the most suitable materials for specific areas.

In some industries, surface finish measurement is necessary to comply with safety regulations and standards such as OSHA. Regulatory bodies such as this have specific requirements for slip resistance in different settings, such as workplaces, public spaces, or residential buildings. As a result, property owners and facility managers can ensure compliance and reduce liability risks by measuring and documenting the surface finish.

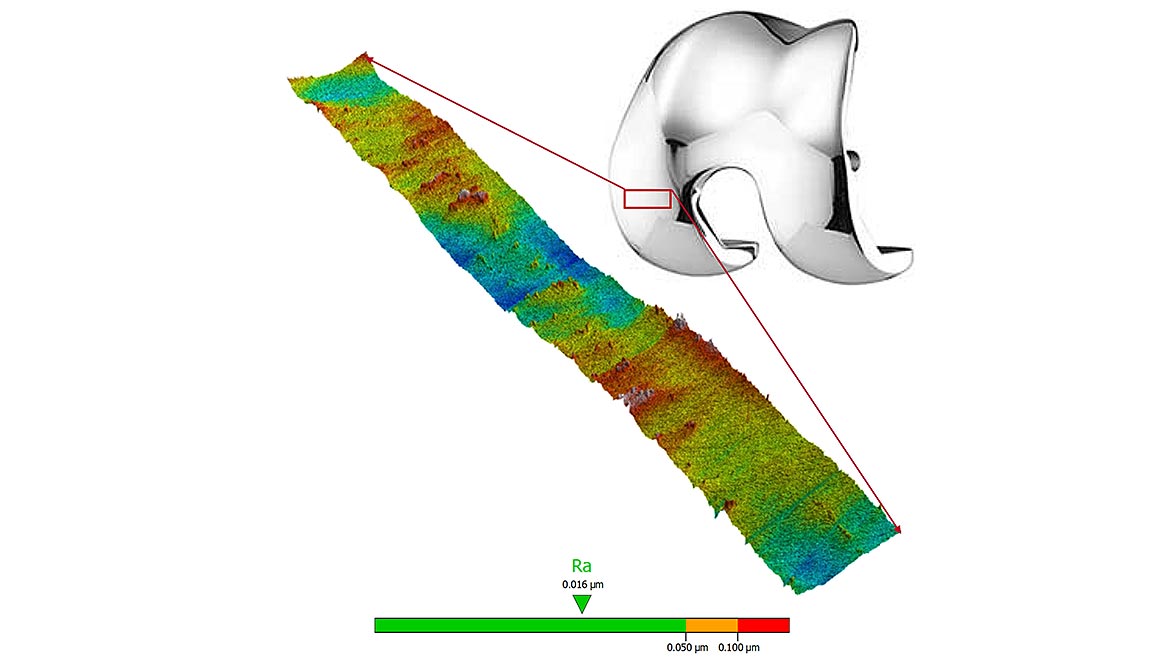

Ensuring the Comfort and Efficacy of Surgical Implants: In this final example, implants for hip replacements will be used as they provide a great example to showcase the spectrum of surface finish measurement. In this type of surgical implant, two components work together to recreate the ball-and-socket structure of the hip joint. This includes a dynamic surface—a femoral head—that can move (such as sliding or rotating while in service). This type of implant has very tight tolerances, as joints must move freely with very low friction. To accomplish this, femoral heads incorporate highly polished surfaces with a near-mirror finish.

The second component, the femoral stem, requires extremely rough and complex features that bones can grow into and adhere to. How well the bone can do that depends on the roughness of that surface and also on how convoluted it is or how much surface area exists for the bone to grow. In this type of orthopedic implant, the surface roughness of the implant’s root portion is essential because it increases the overall surface area, which, in turn, increases the implant’s stability.

By measuring the surface finish, manufacturers can ensure that the implants have the desired characteristics, such as smoothness, appropriate roughness, and optimal friction properties. These factors are crucial in the implant’s ability to articulate smoothly with the surrounding tissues and provide long-term stability and functionality.

Types Of Surface Measurement

Proper analysis of engineered surfaces relies heavily on choosing the optimal measurement procedure. Surface finish measurement methods can generally be divided into contact and non-contact. Contact methods include linear measurement (profile method). This measures roughness on a single line of the sample surface as the tip of a stylus traces across the surface and rises and falls to determine roughness measurements. This surface finish measurement technique can be applied to the examples above, including household paper products, pickleball paddles, golf clubs, and surgical implants.

There are also 3D measurement devices that offer new insights into surface structures and processing. For example, suppose the application requires a more detailed understanding of the surface structure, and information from a single profile is insufficient. In that case, areal 3D measurements can cover a larger surface sampling area to provide in-depth information about the structure/characteristics of a surface.

The leading noncontact methods involve light, or optical measurements, to capture a 3D image of the surface. Light emitted from a tool such as a confocal microscope is reflected to obtain the measurement without coming into contact with the sample. As a result, these systems do not harm the sample and can even measure very soft or viscous materials. 3D surface measurement can be used in the applications above, such as optimizing household paper products and measuring rock/asphalt surfaces, flooring, and surgical implants.

This optical technique creates a topography map that includes highly detailed height information across every point in the measurement area, enabling an accurate representation of complex features. This type of 3D optical measurement is beneficial for more diverse surfaces when there is a requirement to focus on functional structures, including protrusions or depressions, and for determining core parameters and the load-bearing ability of the surface. Furthermore, today’s 3D measurement systems can provide micron and nanometer resolution and acquire more detailed information on surface roughness, depth, volume, flatness, and more.

New confocal microscope technologies enable the nondestructive, material-independent measurement of titanium, stainless steel, cobalt-based alloys, plastic, polymer, ceramics, and other materials, including inhomogeneous and porous surfaces.

Additionally, modern confocal measurement instruments can accurately position samples, making it possible to perform areal roughness measurements on a small target area in a precise location. There is a generation of multi-sensor configurable tools that feature noncontact, five-axis motion control positioning coupled with automation software to measure as many positions required without user adjustment, as well as to allow the system to be adapted to different measuring tasks.

Lastly, stylus-based measurements have been used for decades, and there is a lot of valuable historical data associated with these measurement types. Leading confocal microscope technology will feature results that correlate directly to those contact results, making it much easier for manufacturers to implement this technology.

The Role Of Industry Standards In Choosing The Optimal Surface Finish Measurement Option

Many parameters have been established for the measurement and assessment of surface roughness.

ISO 4287, for example, specifies the rules and procedures for assessing surface texture using stylus profilometers and typically records profiles with lengths of several millimeters. ASME B46.1 details the geometric irregularities of surfaces. It defines surface texture and its components: roughness and waviness. It also defines parameters for specifying surface texture.

There are also ISO standards specific to orthopedic implants, such as ISO 7206-2 and ISO 7207-2, that tell manufacturers about the surface finish as well as additional details about the geometry and the tolerances for making prostheses. For example, ISO 7206-2 covers partial and total hip joint prostheses implants for surgery, including metallic, ceramic, and plastic surfaces. It specifies the sphericity and surface finish requirements for articulating surfaces of prostheses that provide a joint replacement of ball and socket configuration. ISO 7207-2 details components for partial and total knee joint prostheses and specifies surface finish requirements for the articulating surfaces made of metal, ceramic, and plastics.

Furthermore, the basis for worldwide 3D traceability is defined by ISO 25178, which details 3D surface texture parameters and the identification methods. This is the first international standard to consider the specification and measurement of 3D surface textures and cover noncontact measurement techniques. In addition, ISO 25178 created new areal parameters to standardize the results from 3D measuring techniques. These include:

- Hybrid Parameters – Values involve height and spatial dimensions, combining vertical and horizontal information to provide surface angle and slope information.

- Spatial Parameters – Quantify how often the surface features repeat themselves and whether a surface would have varying results when measured in different directions.

- Structure Parameters – Describe functional structures such as grooves for lubricating transport or storage.

The Benefits Of Automation In Surface Finish Measurements

As surface finish measurement increasingly moves to the point of manufacture, adding automation helps establish intelligent quality control operations in the production line to maximize productivity and increase quality and machining efficiency.

Measurement

For surface finish measurement tools to be used in a fully automated measuring process, the equipment must be able to transmit and receive data and controls remotely—including instructions to start a measurement, change surface finish parameters for different parts, set up verification, and more. Fully automated surface finish systems that provide a measuring sequence without operator intervention are ideal for applications where numerous features must be measured with precision and maximum flexibility is required.

Automation has many benefits for surface finish measurement, including:

Making the Right Measurement: Automated processes help ensure the correct areas are measured in hard-to-reach locations and reliable data is generated from the measurements. Furthermore, the proper filters and sampling lengths are automatically applied for reliable results, alleviating the potential for incorrect filters or sampling lengths that may provide poor results.

Increased Speed and Reduced Complexity: Automated measurement tools can enable an incredibly high volume of parts to be very quickly processed, regardless of shape, size, or the type of material that needs to be checked.

Operator Productivity: Automated surface finish measurements allow an operator to use time more efficiently without performing ongoing, tedious, or repetitive movements by hand.

Error Reduction Performing manual surface finish measurement tasks can be very monotonous, increasing the chance of human error. Automating the process removes this risk.

Final Thoughts

Surface finish plays an essential role in a wide variety of applications, from items we use every day to vital technologies. The ability to precisely measure surface finish is crucial to ensuring that engineered surfaces meet specific requirements for quality purposes.

Surface measurement technologies, including contact and noncontact options, have advanced significantly, allowing for more detailed insights into surface structures and processing. Whether measuring surfaces for household products or surgical implants, surface finish measurement is necessary to optimize key product attributes, ensure safety, and comply with regulatory standards. With automation, surface finish measurement processes become even more intelligent, efficient, and accurate, enabling manufacturers to maximize productivity and increase quality.