Software

Software & Analysis

From addressing labor shortages, to reducing human error, the future looks bright for quality inspection software.

Read More

Software & Analysis

Quality Software: Core Qualities to Build Specialist Software Tools in QC Metrology

Manual operations cannot fully meet the challenges of a competitive and increasingly digitized industry.

March 28, 2023

Column | Darryl Seland

From the Editor: Riddle Me This

Aristotle and self-drive cars.

March 14, 2023

Software & Analysis

Make A Quality Part On Time Every Time With ERP Software

With modern ERP software, scrapping non-conforming parts can and should happen in real time.

March 10, 2023

Case Study

A Complete View: Quality Assurance for Premium Headlights

Quality assurance at ZKW Lighting Systems had increasingly reached its limits with conventional measurement technology.

February 10, 2023

Software & Analysis

A Dollar Today Is Worth More Than a Dollar Tomorrow:

How assuming digital maturity is key to quality, competitive advantage, and intelligent technology.

February 6, 2023

Software & Analysis

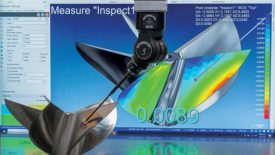

Choosing the Right Measurement and Inspection Software

January 5, 2023

Get our new eMagazine delivered to your inbox every month.

Stay in the know with Quality’s comprehensive coverage of the manufacturing and metrology industries.

SIGN UP TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing