Darryl Seland

Darryl Seland is Editor-in-Chief of Quality magazine. He can be reached at [email protected].

ARTICLES

The Opportunities of Risk in the Supply Chain

Recognizing risks with your vendors can lead to opportunity in the wake of COVID-19.

January 19, 2021

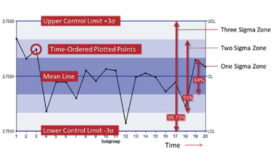

Optimizing Machine Performance with Industry 4.0 and Calibration

Combining the latest in manufacturing technology with concepts that have been around for decades ensure quality products while minimizing unexpected shutdowns.

September 8, 2020

Technology Adoption

The importance of not only how many, but also how quick.

September 1, 2020

Quality in Automation > Automation 101

Automation for Beginners and Experts

Whether a newcomer or grizzled expert, it never hurts to brush up on the fundamentals of automation and robotics.

April 6, 2020

Get our new eMagazine delivered to your inbox every month.

Stay in the know with Quality’s comprehensive coverage of the manufacturing and metrology industries.

SIGN UP TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing