Naturally, much of understanding anything—and where it might be going—is understanding how it began.

Stephen Hawking and other well-renowned scientists attempt to understand our universe, in part, by trying to understand its beginning, a theory commonly known as “the big bang.”

Starting at, or striving for, the where, why, and how of something has even become a part of the nomenclature, now often referred to with a “zero”—Ground Zero (when, where) and Patient Zero (who).

It’s no different with statistical process control, or SPC, minus the zero, perhaps.

SPC was spawned at Bell Laboratories in 1920 by Walter A. Shewhart, the father of SPC, if you will. Well versed in the statistical theories of his day, Shewhart was able to detect differences in the sources of variation of a process. He noted that some of these sources were “natural” to the process; others were not. He began to refer to the natural sources of variation as “common,” or “in control,” others as “special,” or “not in control.” These incites led to his creation of control charts.

Subsequently, he championed his creation of control charts and worked with colleagues on sampling inspection. He collaborated with the army on getting munitions manufacturers to employ his charts and statistical quality control in the production of ordinance for World War II.

Shewhart gave lectures, wrote a book on the subject, and developed a following of notable figures like W. Edwards Deming. In 1945, this following lead to the creation of a professional society that you may be familiar with, the American Society for Quality Control, or ASQ, as it’s popularly referred to today. Shewhart also was instrumental in introducing SPC to post-war Japan.

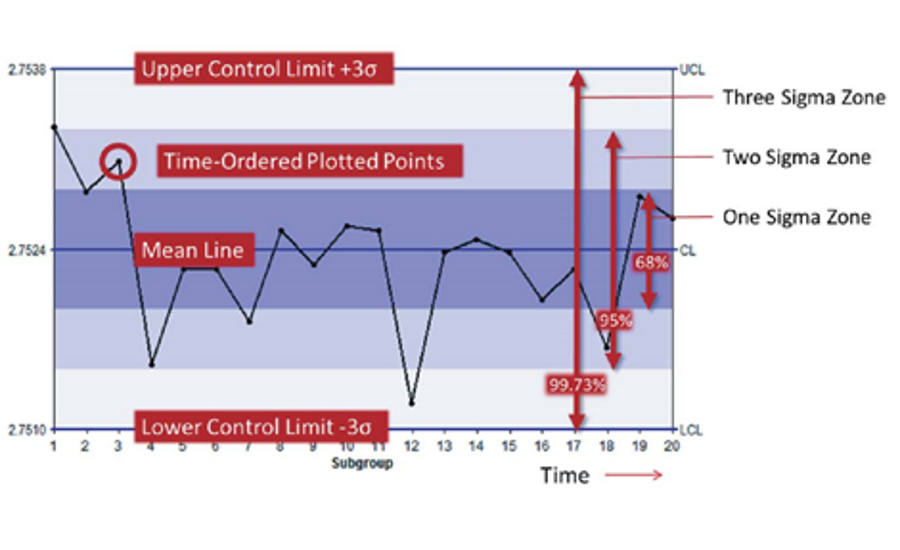

It’s not difficult to see how Shewhart’s early incites and development of control charts could benefit manufacturing, as it did with the munition manufacturers, particularly when needing to control the quality of what’s being produced, like with munitions. Take this example from Wikipedia:

A breakfast-cereal packaging line may be designed to fill each cereal box with 500 grams of cereal. Some boxes will have slightly more than 500 grams, and some will have slightly less. When the package weights are measured, the data will demonstrate a distribution of net weights.

If the production process, its inputs, or its environment (for example, the machine on the line) change, the distribution of the data will change. For example, as the cams and pulleys of the machinery wear, the cereal-filling machine may put more than the specified amount of cereal into each box. Although this might benefit the customer, from the manufacturer's point of view it is wasteful, and increases the cost of production. If the manufacturer finds the change and its source in a timely manner, the change can be corrected (for example, the cams and pulleys replaced).

As with the example above, and a host of other manufacturing applications, SPC in manufacturing is boiled down to three phases:

- Understanding the process and the specification limits.

- Eliminating assignable (special) sources of variation, so that the process is stable.

- Monitoring the ongoing production process, assisted by the use of control charts, to detect significant changes of mean or variation.

This approach has been a hallmark in quality control for quite some time and it will continue to be effective, even more so with the adoption of new technologies to the manufacturing and quality control process, such as software and sensors.

As Pratima Bajpai writes in “Biermann’s Handbook of Pulp and Paper”:

Inventions and new processes change the quality control picture dramatically. The best quality control in the design of vacuum tubes will never compete with the transistor, which is inherently of higher quality for most purposes. Computers and computer networks now make many aspects of quality control essentially automatic to the production worker. Data are collected continuously by sensors, sent to computers, graphed, and presented to operators. Recent trends, warnings of process variables going out of a specified range, and other information are given continuously. This allows the operators to see a potential problem long before the quality of the product is seriously affected. These automatic systems also save money by not requiring much operator time. Much of the drudgery of SPC, such as plotting points by hand, should be gone.

Back in 2013, speaking of the future trends of Process Control in Textile Manufacturing, V. Jain Vedpal wrote:

SPC has become one of the most commonly used tools for maintaining acceptable and stable levels of quality in modern manufacturing. The modern manufacturing environment is focused on computer-integrated manufacturing and the challenges lie in developing advanced computer algorithms and process controls to implement the SPC tasks automatically.

Currently, the focus is on unit process-control methods such as run-2-run (R2R), unit process development and transfer and improvements in the methods to ensure component functionality and reliability. Considerable potential has been identified in the manufacturing of health-related systems and various health-monitoring systems have been developed or are in the development stages.

Much work is being done on the process of prediction and the improvement of product parameters and yield. New methods, which help in process improvement, such as virtual metrology, have been developed, incorporating control density improvement and the reduction of measurement operations. Models for data visualization and analysis are in progress and still more effective models related to process improvement are to be developed.

The modern manufacturing world is demanding more precise and accurate methods for meeting industrial expectations. Advanced process control methods are always necessary across a variety of applications. More sophisticated methods of fault diagnosis are, therefore, being developed by researchers. Sensor implementation and integration with numerically controlled machines are developing rapidly. Investment in sensor technology that provides real time information for modern computer integrated manufacturing is increasing and more research is under way to meet the requirements of industries worldwide.

And Industry 4.0, more automation, robotics, artificial intelligence, and machine learning are just around the corner.