Robert Tremblay

Robert Tremblay is the product marketing manager at Cognex Corp. For more information, call (508) 652-3751, email [email protected] or visit www.cognex.com.

ARTICLES

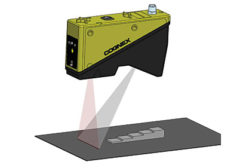

3-D Vision Improves Performance of Challenging Inspection Applications

IN CONTRAST TO TRADITIONAL MACHINE VISION SYSTEMS THAT PROVIDE INFORMATION IN TWO DIMENSIONS, 3-D PROVIDES MORE INFORMATION ABOUT MANUFACTURING PROCESSES.

December 10, 2014

Get our new eMagazine delivered to your inbox every month.

Stay in the know with Quality’s comprehensive coverage of the manufacturing and metrology industries.

SIGN UP TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing