Home » Keywords: » calibration

Items Tagged with 'calibration'

ARTICLES

How to Choose the Right PAUT Probe for Every Inspection

A Comprehensive Guide for Industry Professionals

September 12, 2024

Measurement

How to Read & Interpret ISO/IEC 17025 Calibration Certificates

As an accreditation assessor, I can say that many common assessment deficiencies could have been prevented if the calibration certificate had been thoroughly reviewed.

September 3, 2024

Quality Headline

Beamex US Office to Move to New Location in Atlanta, GA

September 2, 2024

Measurement

Taming the Tension: The Ultimate Guide to Cable Tensiometer Calibration

We aim to initiate a conversation and encourage best practices for better alignment between calibration practices and real-world requirements.

August 19, 2024

NCSLI

The Importance of Close Out Calibrations

Our intent is to bring awareness to the importance of close out calibrations and where not possible as in the case of catastrophic failure, having a system in place that provides confidence that non-conforming parts have not been released.

August 5, 2024

Happy World Metrology Day!

The International Definition of Calibration, Verification, Validation, Certification, and Adjustment

May 20, 2024

Software

The Latest in Calibration Software Trends

Thanks to AI and machine learning, we are seeing new amounts of data change the landscape of the calibration process.

May 7, 2024

Measurement

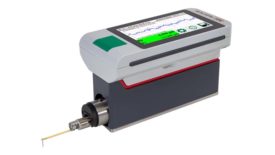

Ensuring Precision: A Guide to Calibration in Surface Finish Measurement

The calibration process for surface finish units is simple but essential to the manufacturing process.

April 12, 2024

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing