Home » Keywords: » data collection

Items Tagged with 'data collection'

ARTICLES

Lean with Lazarus | Ian R. Lazarus

What’s the Big Deal with Big Data?

There is an interesting difference of opinion over how much data should be collected.

June 28, 2024

Measurement

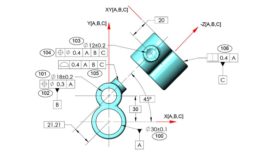

Better Measurement Data Reporting to Improve GD&T Effectiveness

ASME Y14.45-2021 Standardizes Measurement Data Content for GD&T Specifications.

April 4, 2024

Quality Headline

Aionic Digital Appoints Huiza Global Chief Technology Officer

March 15, 2024

Case Study

Orbit Irrigation Digitizes and Simplifies Incoming Inspection Tasks

Until a few years ago, Orbit was tracking inspection data on paper and an Excel sheet.

January 11, 2024

Software & Analysis

Next Steps for Digitalized Quality on the Frontline

Manufacturers looking at replacing paper-based quality processes are being presented with a much broader and more effective set of technologies than ever before.

December 28, 2023

EVENTS

Webinar Sponsored Webinars Sponsored

8/22/24 to 8/22/25

Contact: Meg K.

Unleashing Quality Data: Driving Business Success With Advanced SPC Tools

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing