Home » Keywords: » dimensional metrology

Items Tagged with 'dimensional metrology'

ARTICLES

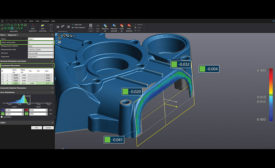

Additive Drives the Adoption of CT for Nondestructive Internal Inspection

CT provides unparalleled insight into a 3D structure, including its density at every point throughout its volume.

November 30, 2020

Dealing With Measurement Uncertainty

The application of uncertainty often brings up questions.

September 15, 2019

INDUSTRY HEADLINE

Mitutoyo America Offers Free Online Video Training and the Opportunity to Earn Certified Credentials

October 2, 2018

High Precision Specialized Gage Blocks

How precise does this master you need have to be?

December 14, 2017

Get our new eMagazine delivered to your inbox every month.

Stay in the know with Quality’s comprehensive coverage of the manufacturing and metrology industries.

SIGN UP TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing