Home » Keywords: » control charts

Items Tagged with 'control charts'

ARTICLES

Control charts should be implemented carefully. Here are best practices to keep in mind.

Read More

Sponsored Content

Detect Small Shifts in the Process Mean with Exponentially Weighted Moving Average (EWMA) Charts

Quickly detecting small shifts in mature or highly sensitive processes is where the EWMA control chart really shines.

February 7, 2022

Control Charts 101

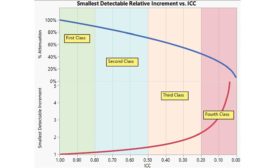

Control charts are straightforward tools that help operators understand process variability. They do this by identifying four process states.

January 7, 2022

The Past is Here

Before you leap forward into another eventful year, let's look back.

January 8, 2020

The Cost of a Poor Measurement System

Convince people of the value of measurement system analysis.

July 1, 2017

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing