Home » Keywords: » image analysis

Items Tagged with 'image analysis'

ARTICLES

Vision & Sensors | Image Analysis

Neural net machine vision image analysis has made rapid advances in recent years.

Vision & Sensors | Interfaces

CoaXPress 2.0 – The Standard in Industrial Image Processing for Demanding Applications

The Newly Developed CoaXPress 2.0 Standard will Increase the Performance of Your Vision System With Twice the Data Rate.

July 6, 2021

Vision & Sensors | Machine Vision 101

Image Analysis 101: The Role of Artificial Intelligence

A Growing Number of Manufacturers are Using Deep Learning Tools, a Subset of Artificial Intelligence, to Reduce Waste and Improve production. But, Experts Say, Some of it is Just Hype.

July 6, 2021

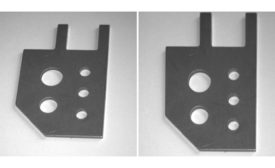

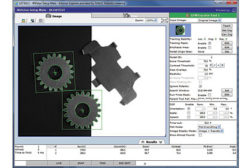

Several Common Image Analysis Software Tools in Machine Vision

There are many different ways that an image can be distorted.

September 1, 2020

Image Analysis for Machine Vision

IT IS THE PART OF MACHINE VISION WHERE THE BULK OF THE ACTUAL “WORK” TAKES PLACE.

September 11, 2014

Vision & Sensors - Image Analysis

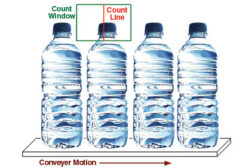

Encoder Input Improves Part Inspection

Adding an encoder to provide a distance-based input trigger can eliminate automated inspection errors.

May 8, 2013

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing