Home » Keywords: » quality assurance

Items Tagged with 'quality assurance'

ARTICLES

Always Looking for the Next Challenge and Continuous Improvement

Read More

NDT | PMI Part 3

Evolution of PMI Technology: Advancements in Handheld XRF Propel Accuracy, Connectivity, and Efficiency

The suite of tools available for PMI has grown.

October 13, 2023

NDT | PMI Part 2

On-Site and Real-Time PMI Testing: Faster Decisions, Enhanced Productivity, and Cost Savings

Learn more about the advantages of positive material identification (PMI) testing.

October 12, 2023

NDT | PMI Part 1

Ensuring Quality and Safety in Manufacturing: The Role of Positive Material Identification

PMI is a vital nondestructive testing method for quality assurance and safety.

October 11, 2023

Software

Harnessing ChatGPT to Develop Calibration Procedures for Test and Measurement Equipment

While AI cannot entirely replace human expertise in developing calibration procedures, it can certainly enhance and streamline the process.

October 4, 2023

Quality in Automation | Industry 4.0

Connected Quality Is the Secret Sauce to the Fulfillment of Industry 4.0

Integrating QC and QA can mitigate product quality risk and empower smarter factories.

April 6, 2023

Measurement

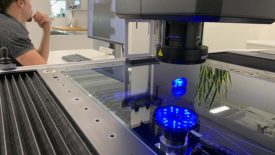

How to Measure the Intricate Components of Electrical Connectors

Quality assurance is critical for manufacturing electrical connectors.

March 30, 2023

Software & Analysis

Quality Software: Core Qualities to Build Specialist Software Tools in QC Metrology

Manual operations cannot fully meet the challenges of a competitive and increasingly digitized industry.

March 28, 2023

The Spending Forecast is Here

The 22nd Annual Quality Spending Survey Results

Concerns about Covid-19 are down, but inflation worries are up.

December 29, 2022

EVENTS

Webinar

9/13/23 to 9/13/24

Contact: Meg M.

How to Reduce First Article Inspection Creation Time by 70-90%

Get our new eMagazine delivered to your inbox every month.

Stay in the know with Quality’s comprehensive coverage of the manufacturing and metrology industries.

SIGN UP TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing