Home » Keywords: » multisensor measurement

Items Tagged with 'multisensor measurement'

ARTICLES

Measurement

In today’s fast-paced industrial environment, the right support and service can make all the difference between a successful investment and a costly disappointment.

Read More

Measurement

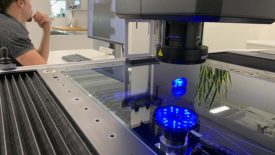

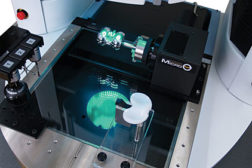

Multisensor Metrology Systems: Quality’s Swiss Army Knife

Always have the right tool for the job.

December 18, 2023

Measurement

How to Measure the Intricate Components of Electrical Connectors

Quality assurance is critical for manufacturing electrical connectors.

March 30, 2023

Boldly Touting Multisensor Value

The value proposition for choosing a multisensor measurement system, compared to a single sensor machine, is productivity and cost savings.

January 3, 2017

The Versatility of Vision Metrology

In the manufacturing world, speed and accuracy are high priorities. Vision technology provides both.

September 1, 2016

A New Era for Multisensor Measurement

Consider how manufacturing processes have been improved by using multisensor measurement.

January 1, 2015

A New Paradigm for Multisensor Metrology

With so many tools, it’s not work—it’s fun.

October 2, 2014

Measurement

Trends in Multi-sensor Measurement

Tactile and optical measurement techniques each have their advantages. Multisensor systems combine the strengths of both.

April 1, 2014

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing