Home » Keywords: » roundness measurement

Items Tagged with 'roundness measurement'

ARTICLES

Measurement

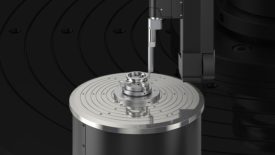

For certain parts and products, roundness measurement is a critical part of the quality assurance process.

Read More

Getting the Best Out of Bore Gages

Data collection capability, careful selection and use are key.

April 30, 2018

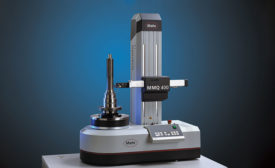

The Next Quantum Leap in Form Measurement

Industry is rapidly shifting towards micron level tolerance requirements.

March 1, 2016

When a Round Peg Is Just Too Square: The Basics of Harmonic Analysis

The technique of Fourier series, or harmonic analysis, has been applied to a wide array of problems, both mathematical and physical.

September 5, 2014

Get our new eMagazine delivered to your inbox every month.

Stay in the know with Quality’s comprehensive coverage of the manufacturing and metrology industries.

SIGN UP TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing