Home » Keywords: » smart factory

Items Tagged with 'smart factory'

ARTICLES

Quality Headline

Hexagon Announces HxGN LIVE Smart Manufacturing Detroit 2020

January 20, 2020

Trends in Automotive Inspection

Intelligent factories, electric vehicles and traceability are just some of the factors that are influencing change in automotive part inspection, say experts in the field.

January 15, 2020

Getting Started with Industry 4.0

The challenge for many businesses is knowing where to begin.

May 1, 2017

INDUSTRY HEADLINE

Hexagon Manufacturing Intelligence Announces Partnership with Wichita State Innovation Campus

February 7, 2017

Large-scale manufacturing

PrecisionPath Consortium Redefining Advanced Manufacturing

Illuminating the challenges, clearing a path to the Smart Factory.

September 1, 2016

Stepping up to the Factory of the Future

Predictive simulation is underpinning the factories of the future through immersive visualization of the vast amount of data from Industry 4.0 components and machines.

September 1, 2016

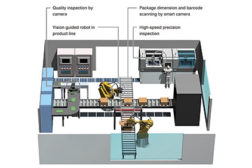

The Dawn of the Smart Factory

INDUSTRIAL SMART CAMERAS ADVANCE AS EMBEDDED VISION SYSTEMS WITH NEW GENERATION PROCESSORS ARE INTRODUCED.

September 11, 2014

Get our new eMagazine delivered to your inbox every month.

Stay in the know with Quality’s comprehensive coverage of the manufacturing and metrology industries.

SIGN UP TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing