Home » Keywords: » variation

Items Tagged with 'variation'

ARTICLES

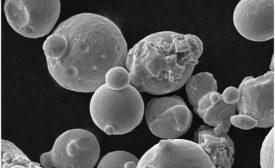

Learn more about the entire 3D printing process from powder characterization to determining the best tests to qualify parts for the aerospace industry.

Read More

Seven Ways Gage Management Improves Product Quality and Enables Growth

Manufacturers can significantly improve their visibility into operations through gage repeatability and reproducibility (GR&R) studies.

June 8, 2018

Dorian Shainin's Influence on Quality Professionals Part IV

Multi-vari and pre-control charts in our final Shainin column.

March 1, 2018

Data Collection War Stories

The most unpredictable factor in almost every process? People.

November 3, 2014

Get our new eMagazine delivered to your inbox every month.

Stay in the know with Quality’s comprehensive coverage of the manufacturing and metrology industries.

SIGN UP TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing