Home » Keywords: » model-based inspection

Items Tagged with 'model-based inspection'

ARTICLES

Measurement

Measuring and verifying the thickness of features is more critical than ever before.

Read More

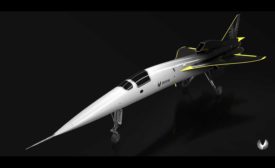

Boom Breaks the Barrier on Enterprise Measurement Solution

It improves quality, increases speed to market, and reduces cost.

February 6, 2020

Reverse Engineering for a Model-Based World

The list of reverse engineering applications is long and will continue to grow as engineers create new and creative ways to use the technology.

November 1, 2019

Model-Based Definition Puts GD&T Data to Work

Quality inspection used to be a disparate process isolated in a lab. Today it is much more integrated with the production floor through in-process inspection and open CAD-based measurement software.

March 8, 2018

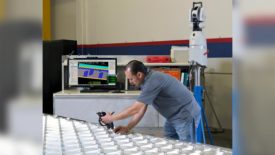

Stevens Manufacturing Conquers Quality with Dynamic Measurement Duo

Portable, multi-function CMM ensures dimensional integrity of every part.

April 1, 2016

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing