Home » Keywords: » Quality in Automation

Items Tagged with 'Quality in Automation'

ARTICLES

Systems Integration

In the rapidly changing and expanding landscape of imaging hardware components and software solutions, the job of systems integration is as important as ever.

Read More

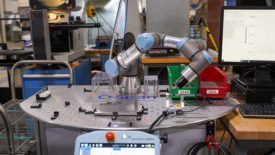

Quality in Automation | Robotics

Advanced Automation Delivers the Ultimate in Quality Control

When considering the type of robot for automating inspection tasks, cobots are often the initial go-to solution.

March 29, 2024

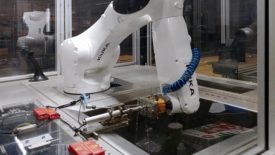

Quality in Automation | Automation

Machine Vision Advancements Simplify, Improve Vision-Guided Robot Systems

3D Imaging, AI-Based Software, and Industrial Computing Democratize Application-Specific Automation Systems.

March 29, 2024

Quality in Automation | Case Study

How to Specify Vision Systems when Automating Measurement and Inspection Processes

Perhaps you already know you want to procure a vision system but are wondering how to go about specifying the system.

March 29, 2024

Quality in Automation | Artificial Intelligence

The Future of AI for Visual Inspection and Visual Quality Control in Electronics

With the rise of AI and the global restructuring of where goods are manufactured, leaders must devise a new strategy for visual quality control.

March 29, 2024

Quality in Automation | Automation

Leveraging automation for quality gains

As automation simplifies and enhances manufacturing processes, quality control staff see significant career advantages, making a shift towards more efficient, consistent, and data-driven production environments.

March 29, 2024

Quality in Automation | Column

Robot sales poised for recovery in mid-2024 due to labor shortages, reshoring, AI

No matter the industry, companies find that to fill labor gaps and improve productivity, automating more manual tasks simply makes sense.

March 18, 2024

Quality in Automation | Quality 4.0

Time for Quality 4.0

Changes in industry are taking place now.

April 20, 2023

Quality in Automation | Robotics

Automated Robotics Are Just Getting Started

These machines are only gaining favor post pandemic.

April 19, 2023

Quality in Automation | Column

6 Trends Bound to Boost Automation Growth in 2023

We expect these trends—and others—to contribute to the growth of automation in 2023.

April 5, 2023

Get our new eMagazine delivered to your inbox every month.

Stay in the know with Quality’s comprehensive coverage of the manufacturing and metrology industries.

SIGN UP TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing

.jpg?height=168&t=1711968358&width=275)