With record registrations coming in for Automate 2024 in May, it’s clearer than ever that automation is poised for big growth in North America. Historically high sales in 2021 and 2022 may have tempered last year for myriad reasons—slow U.S. economy, high interest rates, oversupply from over-ordering in 2022, and fewer new manufacturing and distribution centers being built. Yet this year, companies from all industries are coming to Chicago to see the latest innovations and best practices to be ready to purchase and deploy when they get the green light.

However, some indicators point to a recovery of sales starting in the second half of 2024. We foresee this happening not only in manufacturing and automotive but also in industries such as healthcare, construction, agricultural, and pharmaceuticals. More of these companies now recognize the benefits of automating the dull, dirty, and dangerous tasks that can be so hard to fill by human workers, especially young ones.

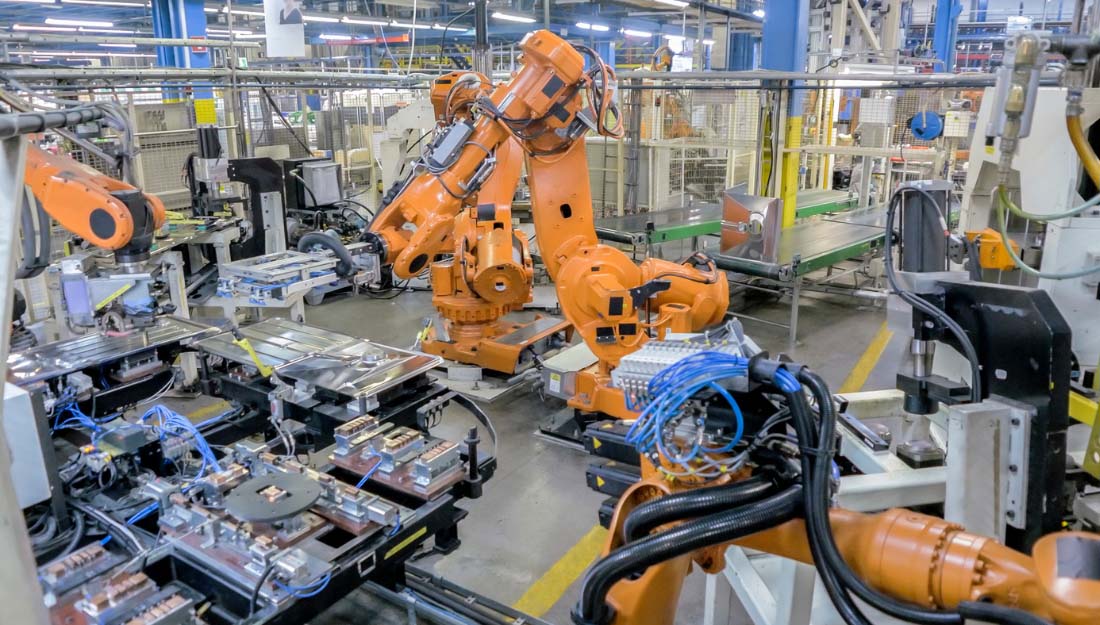

As we talk with A3 member companies in preparation for Automate —both vendors and users—we see several trends playing a big role in the proliferation of robotics and automation across industries.

Labor shortages continue in every industry

U.S. companies from most industries continue to struggle to find human workers. According to a January 2024 report from the U.S. Chamber of Commerce, as of September 2023, all industries have a worker shortage except for nondurable goods manufacturing, wholesale and retail trade, construction, transportation, and utilities. What’s more, according to the U.S. Department of Labor, over 50 million workers quit their jobs in 2022, with 30.5 million workers having resigned in 2023 by the end of August.

As a result, an increasing number of companies are turning to automation. No matter the industry, companies find that to fill labor gaps and improve productivity, automating more manual tasks simply makes sense.

Reshoring and nearshoring trends expected to accelerate

Reshoring and nearshoring of manufacturing appears to be increasing as international labor costs, especially in China, continue to grow while manufacturers face new risks from being extensively dependent on offshoring components or production. In fact, according to a recent Deloitte survey, nearly two-thirds (62%) of manufacturing leaders in the United States and Europe with annual revenues of more than $500 million have already begun reshoring or nearshoring efforts. So far, such efforts show no signs of slowing down. Moreover, according to the Reshoring Initiative's report on the first half of 2023, U.S. companies are reshoring at a record pace. Also, for the first time in two decades, Mexican companies are now sending more goods to the United States than China, according to recent U.S. Commerce Department figures.

This all gives U.S. manufacturers an even greater push to automate, because as they reshore, they cannot find the human labor to take on essential tasks. In any case, companies are finding that the best way to bring manufacturing back quickly—and complete projects or tasks they’re struggling to accomplish—is to automate. Whether these companies began automating within the last few years or are waiting to automate due to economic concerns, we expect to see more robots deployed in conjunction with these reshoring initiatives.

Advancements in AI create more potential robot and vision applications

Artificial intelligence is a hot topic, especially in the manufacturing industry. Large manufacturers in a variety of industries have long been on board the AI/smart automation train. But continued evolution is bringing new and exciting opportunities, with AI-driven solutions now available for nearly every pressing manufacturing issue. Consider these examples of how AI is being used today:

- Leverage data to make automation smarter: System integrator JR Automation recently helped a customer navigate a digital integration among multiple, disparate robotic work cells—with the goal of leveraging data-driven insights to improve throughput and overall control. The JR Automation team leveraged SCADA and MES solutions to enable improved HMI/visualization, recipe management, KPI tracking and reporting, AGV management, alarm tracking, and key telemetry reporting.

- Use advanced vision systems to improve quality control: The next generation of vision systems leverages AI to read and recognize instead of just scanning barcodes. For example, Zebra Technologies helped customer Bosch to implement such a system to further automate its mark-reading and verification process and enhance traceability. Thanks to AI, these systems can now better recognize and interpret more complex characters (with Optical Character Recognition or OCR), features, and flaws in a way once possible only with human intervention.

- Deploy AI to tackling variances. A-based visions systems are also used to handle variances that have made some tasks too complex for traditional programming. For example, Micropsi Industries’ MIRAI enabled an HWL thermal treatment plant in Germany to automate the loading and unloading of highly reflective metal rods, where the rods’ original position and target position could vary. The AI system trained the Universal Robots robot using human demonstrations without having to engage the costly services of coders with knowledge of AI, optimizing cycle times by 20% and ultimately reducing costs and relieving staff of tedious work.

The possibilities of AI already seem futuristic: robots communicating with one another to work more efficiently on the fly, AMRs buzzing around factory floors alongside human workers, and vision systems flagging a single irregular item among a huge batch of manufactured goods. AI is even behind the humanoid robots being introduced by vendors such as Boston Dynamics and Agility Robotics.

At this point, it’s not hard to imagine what future iterations of AI-enabled automation could do; it’s more a question of how. Continued advances in deep learning, optical systems, and motion control technologies will help enable more sophisticated iterations of the automation concepts already within reach.

The discussion on robotics becomes increasingly positive

While robot sales ebb and flow in North America, the conversation in the business world has taken a more positive turn than in years past. In other locations there is a greater focus on the benefits robots offer companies that are struggling to overcome labor shortages and increase productivity, and less on fears that robots might take jobs. Stories continue to emerge about how companies big and small are succeeding in a competitive market because they have used robots to automate certain tasks. Many businesses even notice improved morale and health among human workers who have moved to more value-added tasks.

We look forward to hearing even more stories like these at Automate as we speak with long-time users of automation as well as those new to the technology. It’s clear that the need for automation is strong and there’s a solution for every company.