Home » Keywords: » Artificial Intelligence (AI)

Items Tagged with 'Artificial Intelligence (AI)'

ARTICLES

Vision & Sensors | Vision

If we can bridge the confidence gap between underperforming legacy vision systems and manufacturers’ needs today, the rate of adoption is sure to grow exponentially.

Read More

Quality in Automation | Automation

Machine Vision Advancements Simplify, Improve Vision-Guided Robot Systems

3D Imaging, AI-Based Software, and Industrial Computing Democratize Application-Specific Automation Systems.

March 29, 2024

Quality in Automation | Artificial Intelligence

The Future of AI for Visual Inspection and Visual Quality Control in Electronics

With the rise of AI and the global restructuring of where goods are manufactured, leaders must devise a new strategy for visual quality control.

March 29, 2024

New Product

Kitov.ai Software Platform for Improved Automated Visual Inspections

March 18, 2024

Quality in Automation | Column

Robot sales poised for recovery in mid-2024 due to labor shortages, reshoring, AI

No matter the industry, companies find that to fill labor gaps and improve productivity, automating more manual tasks simply makes sense.

March 18, 2024

Quality Headline

Aionic Digital Appoints Huiza Global Chief Technology Officer

March 15, 2024

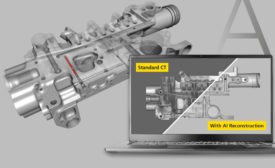

NDT | Force Measurement

Force Measurement and AI: Predicting Product Failure

How AI improves the analysis of data acquired from force measurement to prevent future product or production failures.

March 14, 2024

Edge Learning

How Harnessing Edge Learning AI Technology Simplifies Manufacturing Processes

The combination of machine vision and edge learning is a powerful tool that can aid the manufacturing process in numerous ways.

March 11, 2024

Management

Activating Creative Leadership and Collaborative Teams

Tools for fostering synergy and cultivating collaboration at your company.

February 14, 2024

EVENTS

Webinar

3/26/24 to 3/26/25

Contact: Meg K.

AI for Electronics Quality Control: Practical Applications & Case Studies

Get our new eMagazine delivered to your inbox every month.

Stay in the know with Quality’s comprehensive coverage of the manufacturing and metrology industries.

SIGN UP TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing