Home » Publications » Quality Magazine

Quality Magazine

2023 May

Cover Story

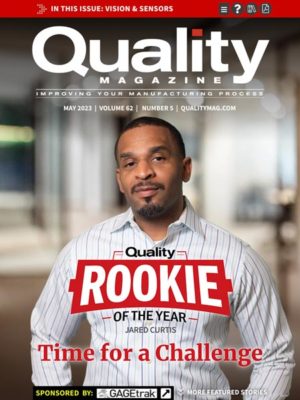

Back to TopInaugural Quality Rookie of the Year Winner

Our Rookie of the Year had twenty years of experience when he decided to switch careers.

Read More

Features

Back to TopQuality 101

Automation in Materials Testing

There are many different parts of a universal testing machine that can be partially or fully automated depending on the specific needs of your lab.

May 15, 2023

High- Speed Measurement

Precision at All Altitudes: High-speed Measuring of Aerospace Parts with Shopfloor CMMs

Quality assurance performed at the site of production can identify and possibly even avoid manufacturing errors.

May 16, 2023

Quality 101

Automation’s Growing Role in Universal Testing

The pandemic proved just how important universal testers are to quality. As staff shorages endure, automation is keeping this technology on point.

May 10, 2023

Software & Analysis

Advanced Quality Inspection Software Offers Many Benefits, But Adoption Lags

From addressing labor shortages, to reducing human error, the future looks bright for quality inspection software.

May 9, 2023

Test & Inspection

Quality Automation: The Role Robotics and Sensors Play in Quality Control and Production

Manufacturers looking to improve their production process efficiency and effectiveness should look closely at Quality Automation.

May 8, 2023

Columns

Back to TopColumn | Darryl Seland

From the Editor: Root Cause

Are we tackling the symptoms of the disease?

May 22, 2023

Speaking of Quality | John Vandenbemden

Auditing vs. Inspection

Even though there are similarities, these tools have different intent.

May 17, 2023

Vision & Sensors

Back to TopVision & Sensors | Sensors

New Sensors and Machine Vision Applications Drive Advances in Optics

New opportunities continually emerge — including in the field of robotics and autonomous machines.

May 22, 2023

Vision & Sensors | Camera Interfaces

CLHS IP Core Enables 25 Gbps Products To Quickly Reach The Market

CLHS uses a proven core that is easy to use, operates at 10g, 25g, and has a roadmap to 50g.

May 18, 2023

Vision & Sensors | Machine Vision 101

Image Processing for Machine Vision – How Did We Get Here?

Machine Learning (ML) has been part of machine vision image processing almost from the beginning.

May 4, 2023

Vision & Sensors | Vision

40+ Years of Vision Guided Robotics

VGR is one of the largest growing sectors in both the robotics and machine vision market.

May 3, 2023

Vision & Sensors | Deep Learning

Can Deep Learning Improve My Manufacturing Process?

By applying DL with a Data-Centric Approach, Users Can Streamline Even the Most Challenging Manufacturing Steps with Fast, Accurate Automated Inspection.

May 2, 2023

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing