For most companies and industries, quality control is one of the most crucial parts of the manufacturing process. When a single small production error can result in massive company losses, it’s clear that investing in better quality control systems isn’t a luxury — it’s a necessity.

But don’t make the mistake of thinking that a non-automated quality control system is your most economical choice. While taking a non-automated approach to quality control may initially appear less costly, the reality is that non-automated systems are only somewhat reliable and require a sizeable human workforce to manage, increasing costs.

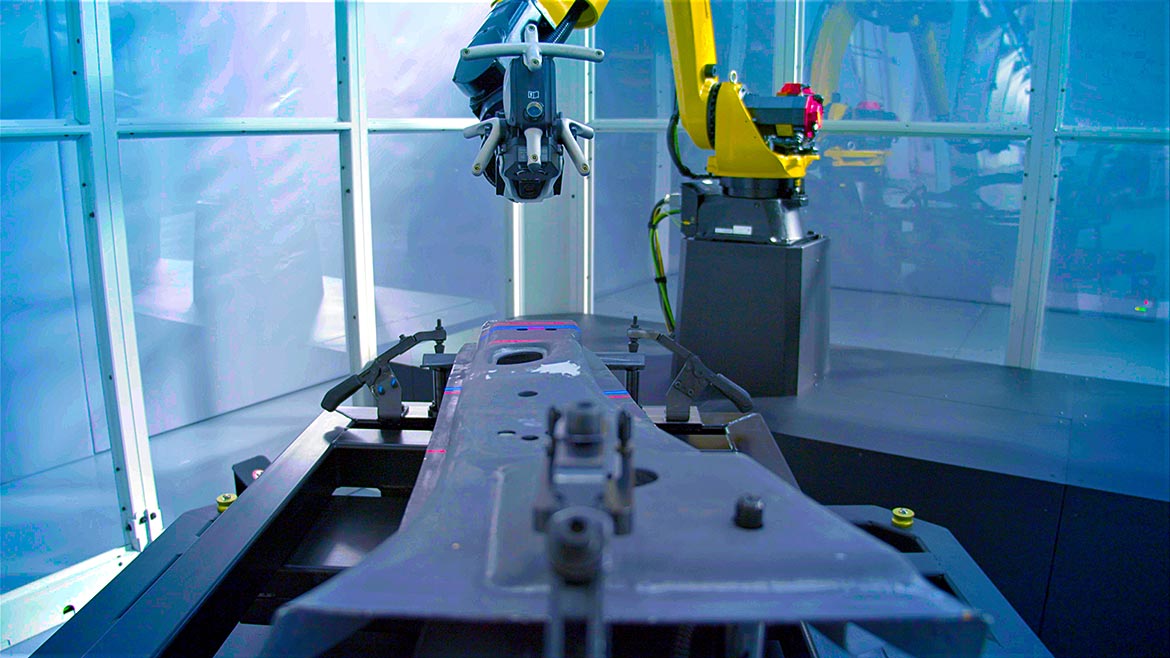

Automated quality control systems improve the manufacturing process efficiency and effectiveness while simultaneously reducing the potential for human error and boosting the final product’s overall quality — and robotics and sensors play a critical role. Let’s take a closer look at the role that robotics and sensors play and the benefits they bring to automation and quality control.

Robotics: Automation, Quality Control & Production

Robotics is just one type of software and technology involved in quality automation, but when used right, they can play a critical role in automation and quality control.

Inspections And Product Testing

One of quality automation’s key benefits is that it improves the speed and accuracy of the inspection and testing processes. With robotics and other automated equipment and software, manufacturers can more quickly and accurately pinpoint product issues and defects during production. Because issues are identified during production, manufacturers can more quickly take corrective action, reducing scrap and the need for rework, leading to time and money savings.

Robotic inspections and testing can also create a competitive advantage. Manufacturing is becoming increasingly data-driven. And manufacturers capable of capturing large data sets that inform quality assurance, process control, and product/process optimization are positioning themselves to take advantage of those insights.

Production Tasks Like Assembly, Packaging, And Palletizing

In addition to improving the accuracy and speed of the production process, quality automation can also positively impact the manufacturing process’s overall efficiency. Robots can handle many routine, repetitive, but necessary production tasks — like assembly, packaging, and palletizing — allowing human employees to focus on more complex, higher-value tasks. This can help boost productivity and efficiency, leading to lower costs and higher profitability.

Quality Control And Production

Another benefit of quality automation and its related elements — including robotic arms, robotic cells, etc. — is that it can help to lessen the potential for human error. When done manually, many tasks and processes related to quality control and assurance are repetitive and invite the opportunity to introduce errors. Automating these tasks allows manufacturers to reduce the potential for human error, helping boost the final product’s overall quality.

Traceability And Accountability

Quality automation also adds traceability and accountability to all aspects of the manufacturing process. Automated systems are capable of storing and tracking product data — including which employees were involved, when and where it was produced, and which specific tools and equipment were used. Manufacturers can then use this data to improve the overall quality of their processes and identify and correct issues that may have occurred during production.

Sensors: Their Role In Quality Control & Production

Waiting on a part to be measured can bring a production line to a halt — depending on the workload of the quality department and the operator’s schedule. Delays can easily add up. But automated tools like sensors can help avoid and alleviate those delays.

Sensors can play a critical role in a manufacturer’s ability to gather data on their products. Leading manufacturers are embedding sensors and measurement equipment into their processes, allowing them to quickly measure every single part, 100%, without waiting for manual part measurement activities.

Laser Scanners

For example, because they can effectively capture 3D shapes and surfaces, laser scanners are sensors that play a crucial role in quality assurance. Industries regularly use laser scanners for geometry and surface quality control, but they can also be used for fit and finish, reverse engineering, and assembly applications. Laser scanners provide dimensional information quickly without disrupting workflows or causing unnecessary interruptions in production. The end result is that manufacturers get the data they need without having to make quality or accuracy compromises.

Hexagon’s Manufacturing Intelligence division PRESTO Automation AS1 Laser Sensor

Temperature Probes And Pressure Sensors

In the production process, sensors like temperature probes and pressure sensors can quickly and precisely gather data that allow operators to make adjustments as needed. Temperature probes provide a fully automated measurement of a part’s temperature at any stage of the machining process, giving manufacturers greater control of production processes and decreasing defects and rework time. And air pressure sensors can measure variations in air pressure that can negatively affect a machine’s performance, alerting operators of potential deviations that require their attention.

Machine Health

Sensors can also measure the machine’s physical condition, allowing manufacturers to extend equipment lifetimes by identifying real-time health trends. Available for use both in the office and in the field, sensors that monitor and measure machine health boost efficiency while minimizing downtime and out-of-warranty repair costs. Operators can gain greater insights into unexplained machine system faults. Real-time alarms and alerts provide operators and maintenance staff with the information they need to prevent minor issues from becoming catastrophic failures. And real-time machine information lets manufacturers more rapidly tweak process controls, which in turn helps deliver less scrap and higher yields.

Product Quality

Sensors don’t just impact production processes; they can positively impact product quality. By augmenting a production line’s existing sensors with specialized sensors focused on tweaking and optimizing production quality, manufacturers can ensure that the product meets production requirements. They will, therefore, also meet customer needs.

Benefits Of Robotics And Sensors For Automation And Quality Control

Robots and sensors positively impact automation and quality control in numerous ways.

Increased Efficiency And Productivity:

When it comes to your production line, time is money; in some manufacturing facilities, being shut down for even a minute costs the company upwards of $10,000 in lost productivity. Depending on your quality department’s workload, you may have to wait to have a part measured — and a five or six-hour delay can wreak havoc on your production process.

Automated quality management allows you to work to maximize the value of your technology investments, keeping the process moving even if human operators are interrupted. In addition, manufacturers can gather data about parts in the production process, empowering them to take quick action to resolve potential issues, saving time and money.

Quality automation not only helps the production line but can also support throughput within the quality lab. Combining laser scanners with robots in a quality lab can reduce inspection time, reduce human error, and free up QA staff to perform higher-value tasks. Automation of CMM inspections is also often overlooked. Users of batch-processing products can again benefit significantly from automation by freeing up QA staff and maximizing CMM utilization. Automation doesn’t call for last-minute meetings or breaks to ensure your investment is measuring its maximum throughput.

Improved Data Accuracy And Consistency:

Digital data logging reduces human error and increases the speed of data availability, helping ensure highly accurate data. Unlike human operators, who may vary in the way they collect and record data, robots perform the same task in the same way, every time, allowing manufacturers to track, monitor, and correct any anomalies. Additionally, long-term data storage allows manufacturers to look back at previous data to quickly determine issues and prove that their parts were in tolerance. This protects companies against potential lawsuits or other legal actions, often shutting down potential litigation issues before they can begin.

Enhanced Safety:

Robotics and sensors also help enhance safety. In the past, an operator may perform an inspection and note — either in their head or on a sheet of paper — that the part was in tolerance. But with increasing regulatory scrutiny, manufacturers need another layer of accountability to show that they’re taking safety seriously. With automated quality management, companies can maintain a data set that captures the date and time the part was measured and those measurement results.

Reduction Of Human Error (Waste, Scrap, Rework):

Catching an issue before it is replicated throughout the production line — leading to waste, scrap, and rework — is critical for many manufacturers. Unlike their human counterparts, robots can perform the same task the same exact way every time. This reduces the chance of introducing human error and decreases waste, scrap, and rework.

A Positive Impact On The Bottom Line

Manufacturers looking to improve their production process efficiency and effectiveness should look closely at quality automation, including using robotics and sensors. By automating quality control and assurance tasks and processes, manufacturers can boost inspection and testing speed and accuracy, increase manufacturing efficiencies, minimize the potential for human error, and enhance accountability and traceability. The massive benefits of quality automation make it a valuable investment for companies interested in positively impacting their bottom line.