Gage Repeatability and Reproducibility (GR&R) studies provide information on measurement system performance by analyzing measurement error from various sources. Typically the sources of variation are divided into three categories: part-to-part, operator or appraiser, and gage or equipment. In some instances another category, interaction between parts and operators, can provide additional information about the gaging process. Not all calculation methods provide the same information or the same result, so it is important to pick an appropriate calculation method.

Methods

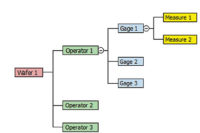

In most GR&R studies, multiple operators measure the same parts in random order to collect data. Most studies use two or three operators and five to 10 parts. In instances such as automated measuring processes, the GR&R studies are not affected by operator influence. These data then are analyzed using a calculation method.

As GR&R calculation methods have evolved, two primary methods have become accepted for most studies using operators and trials: the Average and Range Method, also known as the Automotive Industry Action Group (AIAG) method, and the Analysis of Variance (ANOVA) method. Both methods provide estimates for three measurement error components: repeatability or equipment variation, reproducibility or appraiser variation, and part-to-part variation.

The ANOVA method also can detect an interaction between operators and parts, a situation where the operators and the parts are related to each other, either individually or as a group. For example, a gage measuring the thickness of copper plates in the holes of printed circuit boards may be sensitive to the speed at which its probe is inserted into the hole. Some operators may always insert the probe slowly, while others may insert it quickly in large holes and slowly in small holes. Operators using different speeds with different hole sizes will show an operator-part interaction.

While the AIAG method is popular, the ANOVA method can identify an operator-part interaction. It also provides easy-to-interpret results. The computations are more involved for the ANOVA method, but using a computer to perform the math avoids tedious, complex calculations. Most software packages include the ANOVA method.

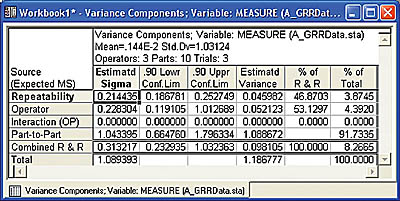

A calculation can produce four possible ratios: Part Variation (PV), Equipment Variation (EV), Appraiser Variation (AV) and in some instances, the interaction between parts and operators. Sometimes the EV, AV, and, when available, the operator-part interaction are combined to produce another ratio, the GR&R ratio. To produce these ratios, the individual components are divided by the total variation using a statistical technique that adds the components together. These ratios typically are reported as percentages. Depending on the calculation method, the results for the ratios will change and influence the ability to interpret the results.

The AIAG method calculates percentage GR&R-the percentage of the total variation consumed by measurement error-EV and AV combined-and

% PV, or the percentage of the total variation consumed by part-to-part variation, using standard deviations estimated from the ranges. These percentages should total 100%-because the total variation was divided into these two parts-but they do not. They consistently total more than 100%, often leading to confusion in understanding the calculated percentages.

To see why these percentages do not equal 100%, suppose there is a square building with a square room in the Northeast corner and one wants to know what percentage of the floor space the room occupies. The length of one wall of the building is 100 feet. One wall of the room in the corner is 10 feet long. The percentage of the floor space occupied by the room is calculated as the room length divided by the wall length, 10 ft/100 ft x 100% = 10%.

But walking inside the building, one sees that this room does not consume 10% of the floor space but considerably less. What went wrong? Of course the error is in the use of the lengths of the walls to calculate the percentage floor space instead of using the areas. Repeating the calculation, it is found that 102 ft2/1002 ft2 x 100% = 1%. The room actually occupies only 1% of the building's floor space.

In this analogy, length corresponds to standard deviation and area corresponds to variance. Variance is the square of the standard deviation. To calculate the actual percentage contributions of GR&R and PV to the total variation, use the variances, as the ANOVA method does. For example, with a GR&R standard deviation of 0.1 and a standard deviation for the total variation of 1, using the AIAG method the calculation yields 0.1 / 1 x 100% = 10%. Using the ANOVA Variance method yields 0.12 /12 x 100% = 1%.

For the AIAG method, the guideline that percentage GR&R should be less than 10% means that the measurement error should consume less than 1% of the total variation. More than 99% should be because of the part-to-part variation. While the AIAG percentages do not represent true percentages of the total variation, the ANOVA method provides the percentage contribution adding up to 100% for each component, providing for easier, more accurate interpretation.

Eliminate influence

With automated test equipment, where the operator cannot influence the measurement, such as using a weighing scale or balance, neither the AIAG nor the ANOVA method should be used.

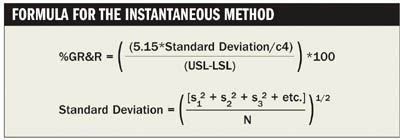

In place of these methods, use the Instantaneous method that obtains only repeatability, or equipment variation, as a percentage of the tolerance. Use at least 10 parts and three trials. To use this method, the calculations follow:

1. Calculate the standard deviation for each part. (s1, s2, s3, etc.)

2. Square the standard deviation for each part above. This is the variance for each part. (s12, s22, s32, etc.)

3. Calculate the average variance. ([s12 + s22 + s32 + etc.] / N, where N is the number of parts.)

4. Take the square root of the average variance in the previous step to obtain the study standard deviation.

5. Divide the standard deviation by the Duncan c4 value if using less than 10 trials. See the table, "Instantaneous Method c4 Values."

6. Multiply the adjusted value from the previous step by the standard deviation spread, usually 5.15.

7. Divide the value from the previous step by the tolerance (the Upper Specification Limit (USL) minus the Lower Specification Limit (LSL)) and multiply by 100.

This method uses only one operator and provides information only on the repeatability, or equipment variation-the measurement error because of the gage itself.

Before using the Instantaneous method it is imperative that the system is free from any reproducibility. If placement on the pan can affect weight measurements for a balance, then different people may measure different weights by placing parts on the balance differently, leading to appraiser variation.

Although several methods of calculating GR&R results exist, two of the most useful are the ANOVA and Instantaneous methods. The ANOVA method calculates the operator-part interaction and calculates the percentage contributions for the variation sources totaling 100%. These characteristics make it superior to the AIAG method. The Instantaneous method provides calculations ignoring appraiser variation, a requirement found in many automated gaging processes. Q

sidebar: Tech tips

• As GR&R calculation methods have evolved, two primary methods have become accepted for most studies using operators and trials: the AIAG method and the ANOVA method.

• Both methods provide estimates for three measurement error components: repeatability, reproducibility and part-to-part variation.

• The ANOVA method can identify an operator-part interaction.

• The Instantaneous method obtains only the repeatability, or equipment variation, as a percentage of the tolerance.