Monday, Jan. 17, 1994, was a watershed date for McMillan Electric Co. (Woodville, WI), says Douglas McMillan, chairman and CEO. That was the day that McMillan met Ashok Thakkar and began what he calls a journey into professional quality management systems (QMS).

Incorporated in 1976, the company began to produce 2,000 electric fan motors per day with about 50 employees. A management team with significant experience in the motor industry coupled with low start-up costs yielded marketplace advantages and for the next 18 years the company remained ensconced in its fan market niche. Economies of scale stemming from a single product coupled with large production runs made it financially successful, McMillan says.

"Yet, this success was slowly evaporating in an almost imperceptible way," he adds. "We were losing ground to foreign competition. We didn't have an effective sales and marketing program, we didn't have a new product development team, and we didn't have a quality management system that could support the additional sophistication that new customers demanded."

McMillan says that product specialization helped the company keep quality at a reasonably good level "for an American company." Approximately 1% of the fan motors were returned under a two-year warranty return policy. "I thought this was acceptable, but I was wrong," he says. "Each time we attempted to diversify into other areas of the motor business, we encountered significant resistance in the area of new product approval. This was primarily because we did not have a reliable quality management system able to guarantee defect-free production and extended motor life."

Realizing his need to improve quality, he turned to Thakkar, president and CEO of the consulting firm ITTI (Roswell, GA). Over the next nine months, McMillan implemented the ISO 9001: 1994 Quality Management System, which included the use of statistical process control, parts to print, quality built into the product rather than high levels of inspection, eliminating warranty returns and improved customer loyalty.

McMillan says that a QMS has helped the company in many ways, including three areas that he calls critical success factors: warranty returns, scrap rate and employee productivity.

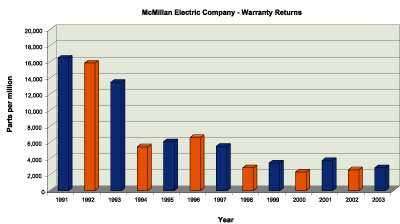

The company's warranty return rate has fallen from a high of 16,000 motors per million in 1991 to a current rate of 2,800 motors per million. While the product mix has changed somewhat over the years, McMillan says the cost of each returned motor averages about $15. This translates into annual savings of more than $200,000 per year.

"We have gained new customers because we have an excellent quality record," he adds. "We retained existing customers because of improved quality systems. While these benefits are difficult to quantify, I can tell you, based on 30 years experience in the motor industry, we probably would have lost a significant portion of our customer base had we not implemented a robust quality management system. Truly, it may have been the difference between remaining in business and going out of business."

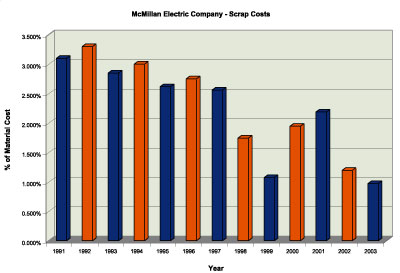

The scrap rate has fallen to below 1% of material used. This has been accomplished by implementing QMS techniques such as increased employee training, preventive maintenance, print control and parts-to-print. If the scrap rate reduction is translated into dollars, McMillan says the yearly material savings from 1991 to now would be more than $500,000 per year.

"There are tremendous soft benefits to a low scrap rate," he says. "Employees are proud of a defect-free product, they enjoy machines that work well, they like statistical process control and they have a great deal more pride in the jobs they perform. This yields pride in their work, pride in their company, and an increased dedication to productivity. While I can't be sure, I would say the soft benefits of low scrap are at least equal to the actual material savings."

Employee productivity has also increased, McMillan says. He attributes part of this increase to investments of several million dollars in new equipment, but added that automation must be coupled with a robust quality management system to be successful. "Training on sophisticated equipment must occur on time and on a regular basis," he says. "Machines must be maintained properly using a robust preventative maintenance system. Set-up instructions, measurement systems, gage calibration-all these quality management system techniques and more-are essential in delivering the high levels of employee productivity required in today's competitive marketplace."

Increases in employee productivity have generated yearly savings of nearly $350,000 per year. In addition to the bottom-line benefits, the company has enjoyed many soft benefits of increased employee productivity.

"As a company, we are far more competitive and far better able to compete against low-cost foreign competition," McMillan says. "Without increased employee productivity, you simply cannot stay in business today."

ITTI LLC

(678) 879-6379

Sidebar: Benefits

• Since 1994, McMillan Electric Co. has saved $1 million a year from the quality management system.

• The warranty return rate has fallen from 16,000 motors per million in 1991 to a current rate of 2,800 motors per million.

• The scrap rate has fallen below 1% of material used resulting in savings of more than $500,000 per year.

• Increases in employee productivity have generated yearly savings of nearly $350,000 per year.