The In-Sight vision system from Cognex Corp. reduced the delivery of faulty parts. Source: Cognex

The Meister Group is a Belgian industrial group that largely caters to the automobile market. With factories in Belgium, France and the Czech Republic, Meister specializes in the mass production of cut steel parts. The challenge facing Meister, whose production units use specialty precision lathes, is that it must manufacture relatively complex parts in seconds, while guaranteeing the conformity of the parts on delivery, without ignoring the essential and continual search for gains in productivity.

In France, the Meister factory is located in Haute-Savoie. It manufactures electric valve parts for automobile equipment manufacturers specializing in ABS braking systems. Nearly 24 multi-spindle lathes produce 120,000 parts each day, representing an annual production of 35 to 40 million parts.

The demand for quality is Meister’s primary focus. In a sector where the smallest incident on an assembly line creates exhaustive investigations and leads to complicated and costly procedures for the subcontractor, the search for zero faults is an absolute necessity. However, given the manufacturing techniques used and the demands of mass production, this goal cannot be attained using only machines. A checking and sorting system is needed to remove defective parts.

Choosing Vision

Previously, sight checks were conducted by human operators, which limited the number of defective parts to around 1 in 1,000. This was unsatisfactory to Meister, so studies were performed to reduce this rate relative to 100 parts per minute. Meister also set to work on reducing the impact of manpower costs on the overall cost of the parts.Consideration of automated checks using vision tools was a natural progression for Meister’s technicians, who already had experience with industrial vision systems for a dimension checking application. A seminar organized by system integrator Alpsitec (Echirolles, France) provided the technicians with additional information on the performance and capacities of In-Sight vision systems from Cognex Corp. (Natick, MA).

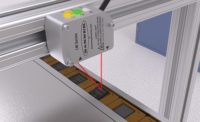

Alpsitec carried out a demonstration to verify that the Cognex cameras were capable of detecting defective parts on the production line. Following this first feasibility test, a prototype was created and assessed for a month. The ease of use of the In-Sight vision systems was a decisive factor in Meister’s order and installation of two test systems at the end of the production line, used to perform a final inspection of each part just prior to packaging.

A robot puts the parts into their mesh packaging. After packaging is complete, the robot picks up the packaged part and places it on the test surface. Then the robot takes hold of the Cognex In-Sight 1000 vision system linked to a lighting system and passes it along the mesh and over the parts. Each part must be inspected for all primary types of defect: the presence of metal shavings, missing components, loose components and damage from knocks or vibration.

The system sends information from the inspection to the robot’s control center. The robot then takes the defective parts and deposits them into a chute, based on the nature of the fault found, where they are then transported to a hopper.

One of the test benches is outfitted with two In-Sight 1000 systems and operates at a rate of 6,000 parts per hour. The other system comprises a single sensor and functions at a rate of 4,000 parts per hour. During the first few months of the operation, both systems worked as dual sorters.

Getting Good Parts to Customers

The bulk of updating the application consisted of identifying the various faults recognizable by the checking systems and teaching these faults to the vision sensors. This procedure is essential for optimizing the efficiency of the inspection system.The rate of faulty parts delivered to customers has rapidly dropped to 40 per every million packaged. The processor algorithms of the In-Sight system and detailed analysis of faults should allow this rate to be reduced even further-to below 20 parts per million.

Jean-Marc Sermet, technical director of Meister France, has supervised this project from start to finish. Sermet is very pleased with Cognex’s products and Alpsitec’s service; the combination has provided him with the necessary skills and experience in installing vision solutions at Meister.

“We were concerned that these test systems would slow down production rates. We have noted with satisfaction that the implementation of these industrial vision solutions does not have a negative effect on production,” says Sermet. “The solution used appears to be particularly stable, and the operators do not have any need to intervene.”

Alpsitec also has trained a technician who has taken charge of setting the vision systems’ parameters. Meister is now able to internally input data for new defects to be identified and modify these parameters in relation to the 15 different types of parts the system inspects.

The greatest reward has been a considerable return on investment in less than six months. The significant improvement in quality has greatly strengthened customer relations, and Meister is now researching additional applications for machine vision on its production lines.

Cognex Corp.

(508) 650-3000

www.cognex.com

Benefits

- Through the use of the In-Sight 1000 systems, the rate of faulty parts Meister delivers to its customers has dropped to 40 per every million packaged.- The powerful processor algorithms of the In-Sight system and detailed analysis of faults should allow this rate to be reduced even further-to below 20 parts per million.

- Meister is able to internally input data for new defects to be identified and modify these parameters in relation to the 15 different types of parts the system inspects.