GigE line scan cameras work with tri-linear technology. Color line scan cameras have finally made their way into a market still dominated by black and white. Source: Basler

One of the most common technologies is the tri-linear color camera concept, as it makes a persuasive argument with mature technology and competitive prices.

Inspection applications for line scan cameras have traditionally used black and white, not color, cameras. This comes naturally because classic line scan cameras typically consist of a single line of horizontally oriented pixels. The line scan inspection procedure is quite easy. The object moves in front of the camera at a certain speed while the camera is capturing an image of the object line-by-line. This is still the most widely used technique in line scan applications.

Driven by two factors, color line scan cameras have finally made their way into a market still dominated by black and white. The first driving factor is that color scanning and copying machines have become more widely used. With a growing market for color scanning and copying, the price for the sensors used in these machines has become attractive for machine vision.

The main principle behind scanning and copying machines is comparable to that of line scan cameras with one major difference. In these machines, the sensor moves in front of the object instead of the object moving in front of the camera. Color detection in scanning and copying machines works by using three parallel lines, one of which is sensitive to red, one to green and one to blue. Each point on the object is captured three times (red, green and blue) and the results are used to calculate the actual color information for each point. This type of procedure is called tri-linear color line scanning.

The second growth driver for color line scan was the demand for a higher dynamic range in black and white line scan applications. To meet this demand, sensors were developed that had two parallel lines instead of one single line. In this case, the sensor was used to capture each point on the object twice, and a binning technique was used to calculate a final value for each pixel. The use of these methods decreased the noise level in the captured images, amplified the signal and increased the dynamic range.

Shortly after two-line black and white sensors were introduced, some manufacturers started to put color filter patterns on the sensors to try to get Bayer-like color pattern performance from the sensors. By applying this two-line color approach in combination with color algorithms in the camera’s field-programmable gate array (FPGA), the market for color line scan cameras was expanded. This essentially took place because a dual-line color line scan concept, as this technique is often called, is simple and cost-effective.

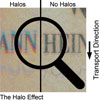

If the camera is positioned so that the sensor is rotated on its short axis, operators will see haloing in the direction of object transport. Source: Basler

Color Concepts

As color has been making its way into line scan applications, three main color concepts have established themselves. The first concept is very simple, but poor in terms of usability and performance for the majority of applications. This concept is based on a single line that is equipped with red, green and blue color filters arranged so that the pixels in the line have a repeating R,G,B – R,G,B – R,G,B pattern.This arrangement, however, has a highly negative impact in that the effective horizontal resolution of the sensor is decreased by a factor of three. This means that a 2,000-pixel camera will only deliver a color resolution of about 700 pixels. In most applications, this is too low to properly perform the necessary inspection tasks, and the single-line concept has not established itself. The second concept, the dual-line approach explained earlier, is more straightforward and delivers good color images. The third concept, tri-linear color, is the most interesting.

A drawback of the tri-linear concept is that if the camera is positioned so that the sensor is rotated on its long axis, haloing effects will appear, as seen here. Source: Basler

The Tri-Linear Concept

The three-line or tri-linear concept works well in a majority of applications. The primary requirement for effectively using it in an application is that the surface of the camera’s sensor-and therefore the lines in the sensor-must be parallel to the surface of the scanned object. When this is the case, all three lines in the sensor can properly capture the relevant color information from each point on the object. This condition must be met to ensure that all of the pixels in the sensor’s lines view the object at the same magnification.Under ideal conditions, the camera collects the data for each of the three colors independently. In terms of image quality, tri-linear cameras are comparable to 3-charge-coupled device (3-CCD) line scan cameras that use three sensors and a prism to split the incoming light beams. Tri-linear cameras have a significant price advantage; they cost approximately half the price of 3-CCD cameras. This advantage has been the key to the resounding success of tri-linear cameras.

A drawback of the tri-linear concept is that if the camera is positioned so that the sensor is rotated on its long axis, “haloing” effects will appear. In this case, the color of the halo visible on one side of the elements in the acquired image will be the same as on the other side. For example, lettering in the acquired image may show orange-colored halos on both sides of each letter.

The haloing is less obvious on elements in the acquired image that are closer to the center of the image. If the camera is positioned so that the sensor is rotated on its short axis, operators will see haloing in the direction of object transport.

Application Example: Color Imaging in Medical and Laboratory Applications

Tri-linear color cameras are popular for use in a variety of medical applications. These cameras are particularly effective in applications that do tissue or slide scanning. Developers have created comprehensive digital systems that benefit their customers with reduced costs, improved operational efficiency and improved productivity.These systems are digital slide scanners that can create a high quality image of an entire microscope slide at high speed. Tri-linear cameras are the perfect fit for these types of applications because the tissues or slides are flat and very small and thus can easily be made to meet the basic requirement of keeping the object parallel to the surface of the camera’s sensor. In addition, today’s tri- linear technology can provide the high color fidelity required by microscopy applications.

By using machines that incorporate a tri-linear color camera, many medical and pathology diagnostic tasks can be performed automatically. These machines are widely used in clinical environments such as hospitals or laboratories. They provide quick, reliable help in oncology tumor diagnostics and ophthalmology diagnostic tasks. They also improve diagnostics for diseases such as diabetes and kidney disorders, and they enable accurate analyses of blood and DNA.