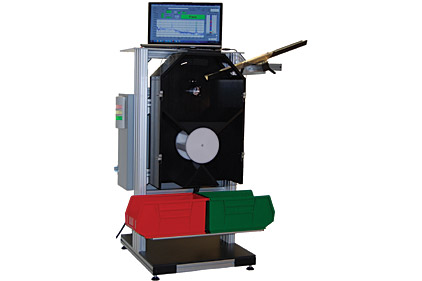

The Drop Test Fixture, Model NDT-DTF2 Resonant Inspection System, allows automated sorting and quality testing of small metal injection molded (MIM), powder injection molded (PIM) and other small parts by using a non-destructive testing technology called Resonant Acoustic Method (NDT-RAM™).

The Drop Test Fixture, Model NDT-DTF2 Resonant Inspection System, allows automated sorting and quality testing of small metal injection molded (MIM), powder injection molded (PIM) and other small parts by using a non-destructive testing technology called Resonant Acoustic Method (NDT-RAM™).

The principle behind NDT-RAM is simple. Every part has a unique resonant signature or pattern that reflects its composition. Any deviation from the expected signature indicates the presence of structural inconsistencies commonly due to flaws or mechanical variations. An intuitive example is a cracked bell that no longer sounds quite right, lacking a clear ring and unable to hold its tone.

The Modal Shop