Surface finish affects how a part will fit, reflect light, transmit heat, wear, distribute lubrication, accept coatings and more. The right finish should ultimately be determined by the part’s function and the engineering requirements of the application.

The proper analysis of these engineered surfaces relies heavily on choosing the right measurement procedure. However, as both tactile and optical procedures can now often be used in surface metrology, the appropriate strategy is not always clear. Three-dimensional measurement devices offer new insights into surface structures and processing alongside established 2D technology. Both are often capable of delivering comparable results.

The best approach depends on the specifics of the individual use case, the related requirements of the target application, and relevant standards requirements.

2D Surface Measurement

TACTILE

ISO 4287 / ISO 13565 describe the surface sufficiently If machining structures are visible and no inhomogeneous surfaces are present

TACTILE SYSTEM

- Entry level devices are very inexpensive to obtain

- Small and mobile solutions are available

- Easy use of the systems

- Measurements inside a bore

- Measurements at complex workpieces with high flexibility

- Worldwide traceability possible through established standards

Roughness and waviness analyses have been an integral part of quality control for close to 100 years. Manufacturers are often required to perform detailed profile measurements in order to inspect any surface imperfections or protrusions on an engineered surface.

Traditionally, one or more profiles of the surface were acquired using a 2D scanning tool to record the key characteristics needed for roughness/waviness measurements. The resulting surface plot shows any deviations across a flat plane when viewed perpendicularly, in order to help identify and quantify the quality of processes and output.

Two-dimensional systems continue to be extremely valuable for use in many industrial profile analyses, and are commonly used for applications where specifications and processes are well defined (technical drawing callouts); applications where the customer or vendor has provided standard operating procedures (SOP) for measurement; and situations where the measurement SOP is well understood/documented.

- The benefits of a 2D measurement system include:

- Small and portable solutions

- Easily accessible with low investment

- Simple to operate and implement

- High flexibility of measuring small to large workpieces

- Measurement at difficult areas, positions or bores

- Established worldwide traceability

When to use 3D Surface Measurement

With the advent of new processes and materials, as well as a more advanced understanding of coating, bonding, lubrication, friction and more, surfaces have an increasingly technical function. The surface structure becomes an increasingly important element to ensure specified performance and longevity.

Structures on state-of-the-art manufactured surfaces are seldom directionally aligned, and instead are distributed stochastically. The randomly distributed structural elements on a surface cannot be seen in 2D. If the application requires a better understanding of the surface structure and a single profile information is not sufficient, 3D measurement should be used.

New surface analysis techniques are being provided by optical technologies using vision, confocal image analysis and interferometry. Three-dimensional measurements using optical measuring devices are extremely useful when there is a requirement to focus on functional structures such as protrusions or depressions, and for determining core parameters and the load bearing ability of surface. For example, when evaluating inhomogeneous and porous surfaces such as ceramics and cast materials, nondestructive, material-independent surface quantification is needed.

This is a portable 3D surface metrology tool.

In these cases, an areal measurement is used to provide more in-depth information about the structure/characteristics of a particular surface. Instead of taking line measurements (as in 2D), high-resolution optical surface metrology systems are used to capture a 3D image of the surface. This creates a topography map that includes highly detailed information about the height, intensity and color across every point in the measurement area, enabling the operator to obtain a true representation of complex features. Furthermore, 3D measurement systems provide the greater statistical certainty achievable with a larger dataset size, and can provide micron and nanometer resolution surface finish and micro-geometry information including: 2D and 3D surface roughness, bearing area, flatness, depth, volume and much more.

- Three-dimensional areal measurement options are a necessity when:

- The piece to be measured is very fragile/delicate and cannot be touched with a stylus

- The surface is too soft, adhesive, discontinuous, etc.

- Coated and inhomogeneous surfaces are being measured

- Porous surfaces such as ceramics and cast materials are being measured

- The feature or features being measured can only be quantified using 3D parameters, such as volume

- Assessing surfaces without machining structure

This is a handheld 2D surface metrology tool.

The use of 3D areal measurements is also valuable when:

- Specifications do not exist or are being developed

- For process development, comparison and optimization

- Researching appearance and properties of engineering surfaces for process control

3D Surface Metrology Examples

Three-dimensional measurement technology is now being used in a wide variety of aerospace, automotive, electrical engineering, mechanical engineering, medical technology, optics and renewable energy industry applications—both in the laboratory or production environment.

An example of a use case that requires 3D surface measurement is in the analysis of textured sheet metal used in the automotive industry. The process for creating the surface of a traditionally rolled sheet steel for automotive applications is very well understood and can be controlled with a 2D measurement. However, over the past decade, laser texturing and patterning have become state of the art. To quantify these surfaces and control these new processes, the analysis of a 3D dataset is necessary.

OPTICAL

OPTICAL AREA MEASUREMENT

- Nondestructive, material-independent detection -> measurement

- Increase statistical significance of ISO 4287 / ISO 13565 parameters (periodic surface)

- Area-based evaluations according to ISO 25178

- Area-based evaluations enable analyses of:

- Surfaces without machining structures and with preferred orientation

- Coated and inhomogeneous surfaces

- Porous surfaces, e.g. ceramics, cast parts

Furthermore, when applying coatings, paint or adhesives, surfaces must have a certain, specified roughness to ensure a sustainable bonding. With a 2D measurement, only specific lines are checked for roughness quality, while a 3D surface analysis provides assurance for a broader area—which can avoid costly process disruptions and bonding failures.

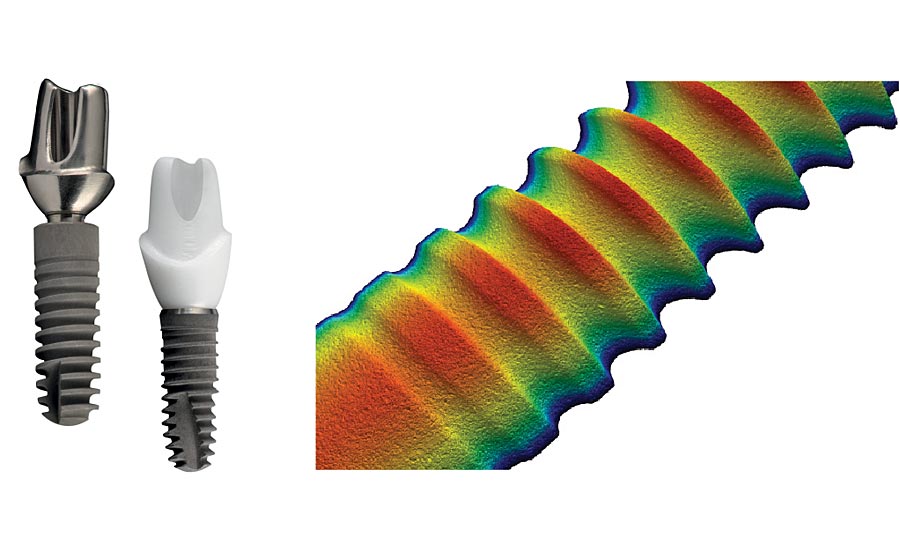

Another example is in the production of orthopedic implants containing a wide variety of materials with greatly varying surface properties. In particular, surfaces where osseointegration is critical require extremely rough and complex features that bones can grow in to and adhere. Dynamic surfaces like the femoral head must be extremely smooth and absolutely defect-free. In addition, there are often plastic, polymer and ceramic components contained within implants. An optical tool has the functional bandwidth and high dynamic range to measure different materials independent of characteristics such as reflectivity or hardness.

The Role of Industry Standards in Choosing the Right Measurement Option

Standards outline the steps required to perform a roughness measurement—for example, generate a resulting Ra value of 1. If the correct standard was followed, all users of that Ra value have uniform information on how that number was produced.

Certain standards require different parameter measurements. Some can be performed with 2D and 3D while some are only possible with 3D measurement (such as a surface parameter that needs an areal versus a single profile).

Two common standards that utilize 2D technology for surface measurement are ISO 4287 and ISO 13565. ISO 4287 details the rules and procedures for the assessment of surface texture using stylus profilometers, and typically records profiles with lengths of several millimeters. ISO 13565 details a filtering method for use with surfaces that have stratified functional properties. These surfaces have a relatively small amount of waviness, and the filtering method suppresses the valley influence on the reference line.

Dental implants can be evaluated for both surface finish and micro-contour.

Both ISO 4287 and ISO 13565 are capable of quantifying surfaces as long as the structures are visible and without inhomogeneities. Therefore, 2D contact (profile) measurement can be used with both the ISO 4287 and ISO 13565 standards.

The basis for worldwide traceability for 3D is defined by the ISO 25178 standard, which details 3D surface texture parameters and the methods for identifying them. This is the first international standard to take into account both the measurement and specification of 3D surface textures and cover noncontact measurement techniques.

ISO 25178 created new areal parameters to standardize the results from 3D measuring techniques. These include:

- Hybrid Parameters – Values involve both height and spatial dimensions where vertical and horizontal information are combined to provide angle and slope information of the surface.

- Spatial Parameters – Quantify how much and how often the surface features repeat themselves and whether a surface would have varying results when measured in different directions.

- Structure Parameters – Describe functional structures such as grooves for lubricate transport or storage.

Conclusion

In many industries and processes, decades of 2D measurement data and experience exist, which made it the de facto standard to measure surface quality. Furthermore, it was and still is completely sufficient for many application and production processes. Three-dimensional measurement can now offer the same—and more roughness parameters in functionality and speed.

As a quick rule, 2D contact is an excellent choice for quick surface finish validation of well-understood products and processes. These techniques are also easily accessible from a budgetary and technical standpoint. Three-dimensional noncontact measurements are the better choice when the surface is technically complex, additional statistical certainty is required, or the material is such that noncontact is needed.

Considering all the different options and standards, it is beneficial to work with a trusted partner that has deep expertise and experience, including a comprehensive understanding of both 2D and 3D measurement technology, to help you determine what technology is best suited for your specific needs.