Home » Keywords: » 2D technology

Items Tagged with '2D technology'

ARTICLES

Vision & Sensors | Vision

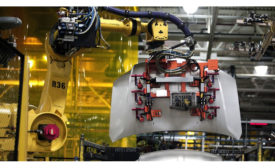

VGR is one of the largest growing sectors in both the robotics and machine vision market.

Read More

Vision & Sensors | Collaborative Robots

Collaborative Automation Delivers Quality Boost

Ease of use is one of the main attractions of collaborative automation.

December 8, 2022

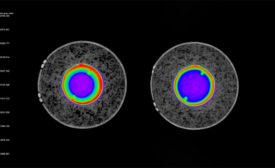

NDT | Radiography

2D Radiography (x-ray) for NDT

2D radiography continues to be essential to the safety and reliability of many of the world's industrial products.

October 11, 2022

Calibration Matters More Than Ever

A manufacturer’s equipment is only as reliable as its calibration levels.

January 7, 2022

The Benefits of Automation

The five reasons to consider, and have been considered for decades, about automation.

December 10, 2021

Sponsored Content

White Paper: University Uses Advanced Micro-CT Scanning for Inspection of Historical Artifacts

October 28, 2021

Inspection Software Evolving to All-In-One QMS Solutions for Practical Data Management

Data-driven manufacturing is here.

September 29, 2020

Sponsored Content

White Paper: Compact 2D/3D Laser scanners with integrated controller reinvigorate profile measurements

August 1, 2020

Computed Tomography: Back to Basics

Computed tomography is a powerful nondestructive evaluation (NDE) technique for both 2D and 3D cross-sectional images of an object from X-ray images.

July 1, 2020

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing