Medical device implants have become increasingly more complex over time as technology has progressed into providing a new way of construction by the means of 3D printing, also known as additive manufacturing. Additive manufacturing has allowed for the implants to be manufactured with complex geometries that traditional manufacturing cannot achieve. This culminates in the ability to provide biological benefits leading to better patient outputs as well as structural advantages by creating complex features.

Additionally, being able to manufacture these devices to conform to a patient’s anatomy is a game changer. The increasingly minimally-invasive additively manufactured implants mean less risk of complications or need for further surgery in the future. When patient satisfaction increases due to smaller implants, the whole industry grows.

In 2018, the medical device implant industry was worth $96.6 billion and is projected to be worth $143.3 billion by 2024. This kind of growth can be attributed to a few things: advanced technology, more complications with health concurrent with a longer lifespan, as well as an increase in a consumer’s inclination towards body aesthetics and physical appearance.

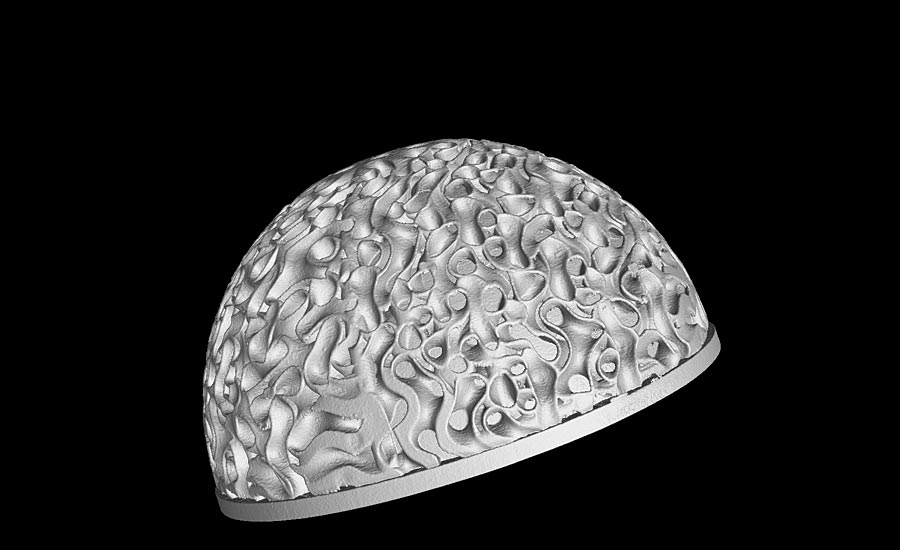

This is a prototype acetabular cup for total hip replacement.

In depth look at 3D printing

Additive manufacturing has evolved extensively over the years such that multiple techniques have been created in conjunction with faster printing speeds. These techniques form solid material by adding multiple thin layers of material in a sequence. One such technique uses a laser to fuse together powder in order to create a solid part. Being able to print layer by layer allows complex parts to be printed as said earlier. In addition to the complex geometry, printers can utilize all different kinds of materials, not just plastics and metals but even mediums like bio ink—biomaterials laden with cells and other materials for growth—that allow for printing of organs.

Why Computed Tomography (CT) X-Ray Technology is needed

A challenge of metal 3D printing comes when there is an inconsistent thermal gradient as the layers are fused together. This will create voids or cracks within the implant during cooling. When cracks and pores exist within the implant, its structural integrity can be compromised and therefore weakened. These defects can be difficult to locate especially if it is internal. How do you identify the cause and location of the defect to further improve the design? By using X-rays.

1. CT can capture the smallest of details.

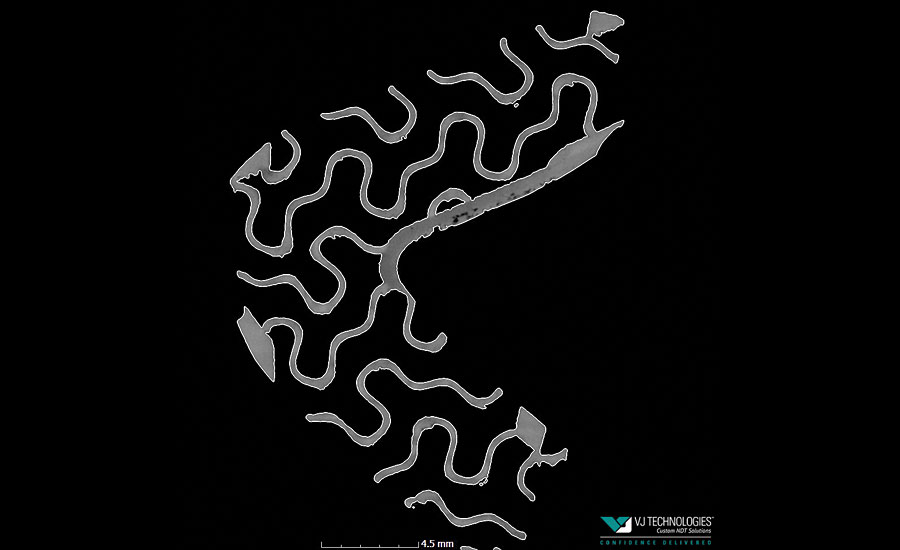

Scientists believe that the use of X-rays rather than thermal imaging devices can uncover the secrets of pit formation. Scientists at the Department of Energy’s SLAC National Accelerator Laboratory are using two different X-ray techniques, one that captures micron-resolution images of what happens as the layers of metal build up, and another that bounces X-rays off the atoms in the material to analyze its atomic structure as it melts and then cools. The benefit of having a system that can perform computed tomography scans is that it can also perform digital radiography or 2D images. This will allow users to see details as small as 5 microns.

Section views of prototype acetabular cup showing exact surface morphology distribution.

2. CT can help standardize quality control.

As more additively manufactured implants are being made, quality control has become very important. The integrity of the device must be sound or else any kind of defect can cause the device to break down or malfunction when implanted. However, many 3D printers may produce products that are inferior to those made through traditional manufacturing.

The best way to standardize something is to keep a consistent record of what the part looks like based off the parameters. Quality and safety are of the utmost importance when it comes to 3D printing and CT is the best nondestructive way of assessing quality.

3. Helps improve design

Computed tomography can also help improve design. CT allows different kinds of analysis like simulating structural mechanics to see how the implant will compress under pressure, porosity analysis to look for defects, and even powder analysis to determine cell structures in porous and filter materials.

“Being able to see exactly how a structure will build and then compare the digital CT scan back to the master model from which the part was printed allows for additive contract manufacturers’ to have the confidence in knowing the process is under control,” says Matt Shomper, director of engineering at Tangible Solutions.

Being able to analyze the implant to such a degree can allow designers to modify the shape to enhance the integrity in areas where it is structurally weaker. For designs where tolerances are very tight, wall thickness analysis can create an extremely accurate measurement.

We teamed up with Tangible Solutions, a contract manufacturer of titanium orthopedic implants to scan prototype samples of their additively manufactured implants shown with this article. We were able to see all the details on the surface as well as the inside, perform porosity tests and analyze the 2D slices.

Overall, computed tomography is a supplement to additive manufacturing and will help grow the industry. Utilizing CT as a quality control tool can help deliver the promise of better healthcare products for patients worldwide.