Over the last few years, collaborative robotics has come to the fore as a way to increase manufacturing flexibility and improve ROI. When considering a human-robot collaborative workcell, we explicitly incorporate and expect humans to be safely working close to and/or interacting with the robot during operation. How this interaction takes place has been extensively analyzed , and the potential approaches are as varied as the range of applications. And the economics of human-robot collaboration can be compelling.

The conventional wisdom in human-robot collaboration is to use a Power and Force Limited (PFL) robot. However, PFL robots are limited in payload and speed in order to remain safe upon human contact. Hence, if your application involves larger payloads, higher operating speeds, or there are other hazards in the workcell or on the robot the benefits of PFL are eliminated and might as well use a traditional robot. And pretty much any robot out there can be made collaborative through Speed and Separation Monitoring (SSM).

In this article, we step back and consider a general approach that could be helpful when incorporating human-robot collaboration in manufacturing. Our analysis hinges on the fact that workcell operations have a cycle time and the level of human interaction is dependent on the application, its design, and operation.

Although in principle most human interactions could be “automated away” (reducing the level of collaboration), it may not be economically or technically feasible to do so while retaining manufacturing flexibility. In other words, there is no ROI to the automation effort – it costs too much and takes away the flexibility that humans provide. In that case, retaining human input into the process through human-robot collaboration is very frequently the best approach.

The Cycle Time Continuum

First, note that pretty much all manufacturing workcells (collaborative or not) are repetitively performing some discrete manufacturing step (assembly, weld, paint, package, palletize, you name it) on a sequence of workpieces that are “fed” to the workcell, “worked on” by an amount of time (the cycle time ), and the process repeated with the next workpiece. Some examples:

A workcell consisting of a robot feeding metal parts to a CNC for deburring. Every deburring step takes, say, 10 seconds and the robot is feeding the parts to be deburred from a bin holding 20 input parts and putting the finished parts on a bin holding 20 output parts. Then, roughly at a cycle time of 200 seconds, there needs to be a machine tending operation where a bin with unprocessed parts needs to be brought to the robot and similarly a bin with processed parts needs to be removed from the workcell.

If the CNC step were, instead, a machining step and it took 30 seconds with each part fed individually (with or without a robot), we would need an operator load station to feed parts directly to the machine at a cycle time of 30 seconds.

Or, perhaps a palletizer (or depalletizer) where a pallet is assembled (or disassembled) every four minutes (240 seconds) and full (or empty) pallets need to be brought in and out of the palletizer.

Or, consider a parts presentation application, where the workpiece is “presented” to a human or an automated system for processing: cabling, fastening, quality assurance, parts attachment, etc. This presentation can occur multiple times in the same cycle (as in the video of Veo Robotics CTO Clara Vu performing three assembly and QA steps on an appliance).

All these applications run the gamut of cycle times from a few seconds (for example, single-part machine tending) to minutes, as would be the case of the palletizer or the multi-step processing of a complex workpiece such as a large appliance or an automobile.

The Human Interaction Frequency Metric

The design and operation of the manufacturing application will determine how and how often the human and robot will collaborate. At one extreme, there is no collaboration, and the application runs unattended throughout the operating cycle. In that case, a simple and sturdy cage with a lockout/tagout mechanism is sufficient to isolate humans from the robots.

At the next level, it could be that the application requires the simplest form of “collaboration” where the robot and human are in proximity to each other but do not really interact with each other during robot operation. In that case, a PFL robot, a light curtain, or 2D scanner could be sufficient for peak cycle time performance.

The applications discussed above all fall in the “definitely collaborative” category; the only question is how often human interaction occurs. In the case of an operator load station with a human feeding parts one by one to a robot or a machine, the interaction is once per cycle, which can be every few seconds. For a palletizer, it is twice per cycle—once to bring in an empty pallet and once to take out a full pallet. But the cycle is much longer, perhaps in the range of minutes. And in the case of parts presentation, this interaction could be multiple times per cycle. The opposite end of the continuum is also possible where interaction occurs every few cycles, for example in the case of a machine tending application where many output bins can be handled automatically before human intervention is required.

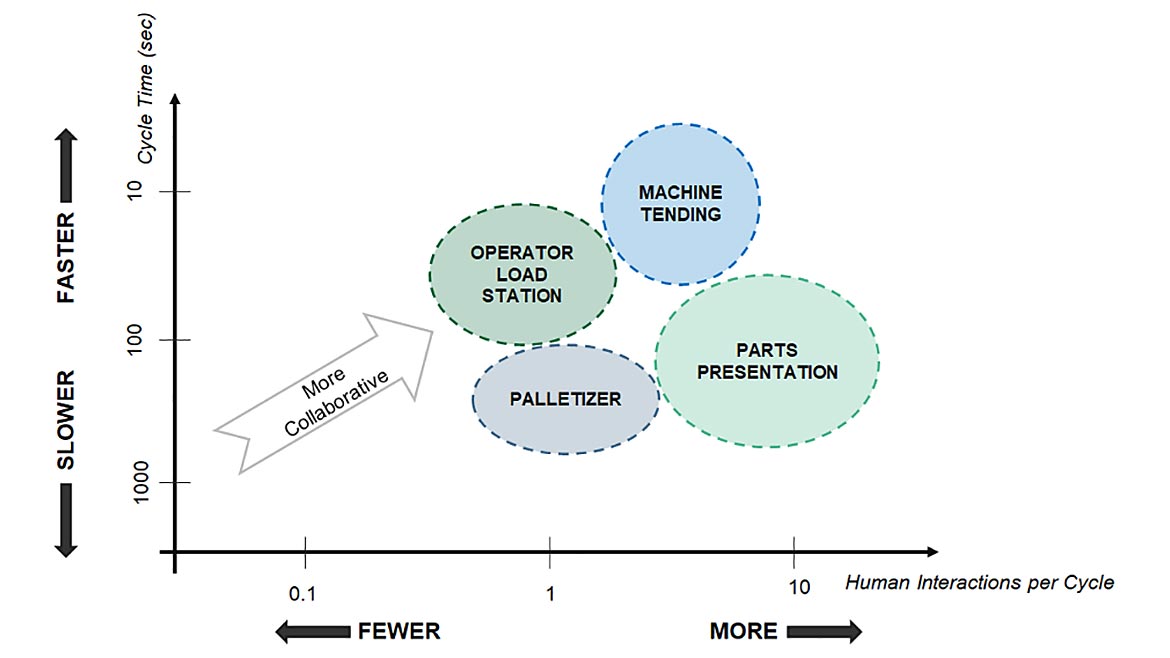

We can take these applications, and others not discussed, and the two metrics—cycle time and human interaction frequency—and plot them on a graph, as in Figure 1.

Figure 1 (Click on the image to enlarge.)

A simple conclusion is that the more human interactions across time, the more “collaborative” the application. This happens as cycle time gets shorter and the interactions per cycle increase. If we can optimize this interaction time, we would improve the efficiency of human-robot collaboration, lowering production costs and enhancing manufacturing economics.

References:

- See for example, Bdiwi et al, A new strategy for ensuring human safety during various levels of interaction with industrial robots or Federico Vicentini’s Terminology in safety of collaborative robotics for a good review of practical human-robot collaboration.

- At Veo Robotics, we have delved into this question before, where we found benefits in lower capital expenditures, faster cycle times, shorter fault recovery, and lower reconfiguration costs.

- This fact is not adequately appreciated. All forms of ISO ISO 10218-1 certification for collaborative workcells require that the robot itself have 3rd-party certified Category 0 and Category 1 stops per ISO 13850 or ISO 60204-1. Every robot sold commercially has 3rd-party safety certified Category 0 and Category 1 stops.

- To be clear, we are defining cycle time as the time it takes to complete a single process step, not the time to complete the whole manufacturing process (which is more precisely the inverse of the throughput, or units per unit time).

- Except possibly for routine maintenance, unexpected repairs, or fault recovery during operation.

- In reality, the interaction is likely to be more than twice per cycle as, on occasion, there could be a dropped box or misaligned box that requires human intervention to correct.