Bill Tandler

Bill Tandler is president and founder of Multi Metrics Inc. (Menlo Park, CA). For more information, call (650) 328-0200, e-mail [email protected] or visit www.multimetrics.com .

ARTICLES

Measurement

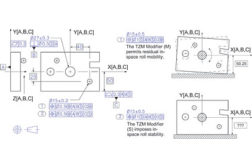

For the sake of industries around the world, it is time to make GD&T much easier to use, and much easier to use correctly.

Read More

Empowering GD&T

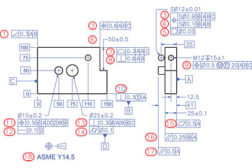

Based on the ASME Y14.5 2009 Standard. Without GD&T, manufacturing is a guessing game.

June 1, 2017

GD&T Workshop

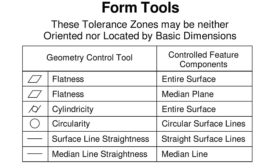

GD&T Functionality

A good way to learn more about GD&T is to critique its application.

January 3, 2013

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing