Articles by David L. Dechow

Techniques for putting the latest technologies and components to work in your applications.

Read More

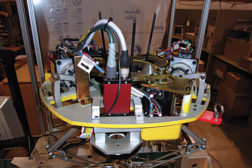

Practical VGR: Cutting-Edge Technologies and Applications

Let’s look at some of the latest vision and robotics technologies and related applications.

January 1, 2018

Top Seven Guidelines for Successful Systems Integration

AT SOME POINT, SOMEONE HAS TO MAKE IT ALL WORK.

December 16, 2015

Machine Vision Color Analysis

AN ENTRY-LEVEL OVERVIEW AND PRACTICAL GUIDE TO THE SUCCESSFUL IMPLEMENTATION OF COLOR ANALYSIS USING MACHINE VISION IN AUTOMATED INSPECTION AND ON-LINE QUALITY CONTROL APPLICATIONS.

July 8, 2015

Machine Vision Inspection Software

AN ENTRY-LEVEL TUTORIAL IN THE STRUCTURE, FEATURES, AND DIFFERENTIATION OF THE SOFTWARE USED IN TYPICAL MACHINE VISION SYSTEMS.

March 3, 2015

Image Analysis for Machine Vision

IT IS THE PART OF MACHINE VISION WHERE THE BULK OF THE ACTUAL “WORK” TAKES PLACE.

September 11, 2014

Standards

USB3 Vision: SuperSpeed for Machine Vision

IT APPEARS LIKELY THAT USB3 VISION AND GIGEVISION WILL EMERGE AS THE FRONTRUNNERS FOR CAMERA SELECTION IN GENERAL PURPOSE INDUSTRIAL IMAGING AND MACHINE VISION.

March 3, 2014

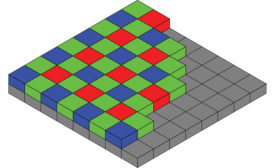

Fundamentals of 3-D Machine Vision

Machine vision capability is expanding rapidly beyond 2-D images.

January 3, 2014

Vision & Sensors - System Integrators

Machine Vision Integration: Behind the Camera

Consider these factors in the selection and implementation of digital cameras in machine vision applications.

July 8, 2013

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing