Home » Keywords: » composite material testing

Items Tagged with 'composite material testing'

ARTICLES

Back to Basics: Flexural Testing for Plastics

A look at flexural test methods and ASTM D790

March 1, 2018

Automated Inspection of Critical Aerospace Components and Structures with Complex Geometries

As aerospace parts are becoming more and more complex, fabrication and materials automated inspections will become the only viable inspection method.

July 1, 2017

Quality 101

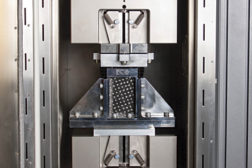

Mechanical Testing of Composites

The mechanical testing of composite materials involves a range of test types, a plethora of standards, and the need to condition and test in a variety of different environments.

July 1, 2014

Get our new eMagazine delivered to your inbox every month.

Stay in the know with Quality’s comprehensive coverage of the manufacturing and metrology industries.

SIGN UP TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing