Home » Keywords: » custom gaging

Items Tagged with 'custom gaging'

ARTICLES

Measurement

There are myriad ways to breathe new life into existing gages without the need to invest in new gaging.

Read More

Crystal Ball Gazing: Gage Trends and Metrology

When you look at how far gages have come in just the last 20 years, you might wonder what, if any, types of technological enhancements might be on the horizon.

December 2, 2019

Analyzing and Reporting Tensile Data on Force Measurement Systems

Using readily available tools such as graphs, tolerances, comments, and test criteria ensures that the required tensile information is on hand when needed.

June 1, 2019

Custom Gages: You’ve made it, but can you inspect it?

Sometimes the only inspection solution is a custom gage.

January 1, 2019

Standard Gage or Custom? How to Analyze Your Gaging Requirements

How to analyze your gaging requirements. Learn how to specify the gaging solution that provides the best results.

May 1, 2017

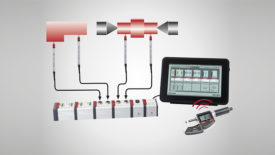

Custom Gages Automate Your Production

Fully automating the measuring process is the ultimate custom gage solution

September 1, 2016

INDUSTRY HEADLINE

Mahr Federal Introduces MarSolutions Engineered Metrology Team

April 1, 2016

Custom Gages to Go: When You Want To Have It Your Way

Many standard off-the-shelf gages no longer provide the right solution for today’s parts. That’s where custom gages come in.

August 4, 2014

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing