Home » Keywords: » inspection process

Items Tagged with 'inspection process'

ARTICLES

NDT | Eddy Current

The inspection challenge in such situations consists of automating the inspection process.

Read More

NDT | Back 2 Basics

Industry Trends: Third-Party NDT Certification Programs Advance Digital Expertise, Standardize Industry Practices

The public deserves to have confidence in their NDT professionals.

June 12, 2023

Medical

Best Practices for Validating CMM-based Inspection Processes

What does a thorough validation approach really entail?

June 1, 2023

Vision & Sensors | Lighting

Three Challenges In Machine Vision Lighting Today And How To Solve Them

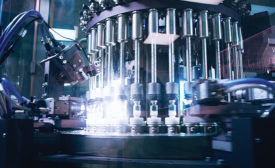

With increased speeds, dynamic production lines, and advanced inspection processes, smart automated lightng is driving machine vision solutions.

May 1, 2022

NDT | Ultrasonics

Automated Inspection of Wind Blades Using a Collaborative Robot

Improve the nondestructive inspection workflow using the latest technology.

April 1, 2022

Improving Your Manufacturing Productivity and Quality with CMM Networking and Automation

Consider automating and moving your CMMs to the shop floor.

January 1, 2020

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing