Home » Keywords: » Radiographic testing

Items Tagged with 'Radiographic testing'

ARTICLES

NDT Trends

Manual means of performing NDT and human evaluation of the results is trending more and more to automated, digitized and artificial intelligence interpretation of the results whenever economically possible.

Read More

NDT of Medical Devices

NDT methods play a critical role in the quality assurance of medical devices.

November 29, 2020

NDT Trends

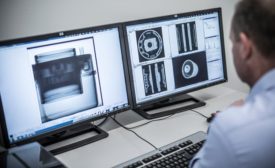

Remote Evaluation of Radiographic Images

Let’s examine the application of remote radiographic evaluation and the subsequent commercial benefits for business.

August 5, 2020

Radiographic Image Interpretation: Doing it Right

The process of radiographic interpretation consists of many variables with the major objective being achieving the highest possible quality level.

June 11, 2020

Advertisement

Weld Defect Imaging and Characterization Using PAUT and TFM Ultrasonic NDT

July 30, 2018

Human Factors Affecting Disagreements Among Interpreters

In the second part of a two-part series, we look at factors affecting probability of detection.

November 1, 2016

Testing, Trust, and Traceability

You can often re-inspect a part, but there’s no way to restore lost traceability

August 1, 2016

Get our new eMagazine delivered to your inbox every month.

Stay in the know with Quality’s comprehensive coverage of the manufacturing and metrology industries.

SIGN UP TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing