Home » Keywords: » retrofit

Items Tagged with 'retrofit'

ARTICLES

Retrofits: Ensuring the Reliability and Capability of Your Universal Testing System

When considering legacy equipment in your lab it is important to recognize what makes a good candidate for a retrofit.

October 1, 2019

The Value of One Software for Several Types of Inspection Systems

A common software for multiple instruments, often from multiple OEMs, is ideal.

April 2, 2019

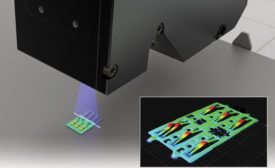

Designing a Better Sensor for Small Parts Inspection

Smart technology advancements are at the heart of today's movement toward better sensor design.

March 1, 2019

Test & Inspection

To Retrofit or Not to Retrofit: When Your Universal Testing System Gets Old

It is possible to retrofit almost any older testing system. The question is whether the investment is worthwhile.

July 1, 2016

Get our new eMagazine delivered to your inbox every month.

Stay in the know with Quality’s comprehensive coverage of the manufacturing and metrology industries.

SIGN UP TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing