Home » Keywords: » NIST

Items Tagged with 'NIST'

ARTICLES

Vision & Sensors | Inspection

Exploring Integrated Optical Inspection Systems

For noncontact surface characterization of manufactured materials.

March 6, 2023

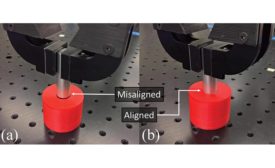

Helping Robots Stay on Target

Both accuracy and repeatability are key performance characteristics that influence the robot's ability to meet a manufacturing process's needs.

December 2, 2019

Large-scale manufacturing

PrecisionPath Consortium Redefining Advanced Manufacturing

Illuminating the challenges, clearing a path to the Smart Factory.

September 1, 2016

Management

Smart Manufacturing: A Digital Leap Forward

Call it Industry 4.0, the Connected Enterprise, or the Industrial Internet of Things, but this fourth manufacturing revolution is just getting started.

June 1, 2016

Applying Measurement Uncertainty

IT IS PART OF EVERY MEASUREMENT MADE BY ANY SOURCE.

November 3, 2014

INDUSTRY HEADLINE

MEP Launches Competition to Fund Manufacturing Centers in 10 States

August 4, 2014

Get our new eMagazine delivered to your inbox every month.

Stay in the know with Quality’s comprehensive coverage of the manufacturing and metrology industries.

SIGN UP TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing