CINCINNATI — Exact Metrology hosted an open house at its facility in Cincinnati and the event was attended by over 100 local area companies, comprising quality assessment, design engineering and management personnel from many of the leading manufacturers in the region.

Hosted by company co-president Steve Young, the day included ongoing product demonstrations of the various metrology equipment brands offered for sale, lease and rental by Exact, as well as the testing procedures provided as a service by this unique metrology supplier. One highlight of the event was the company’s new partner, EnvisionTEC, a builder of 3D printing equipment for myriad industries, for whom Exact was recently named Midwest dealer. Also on display were a number of the other equipment lines represented by Exact, including Romer arms, GE CT scanning, Leica 3D imaging scanners and a variety of point cloud software advancements for the quality world.

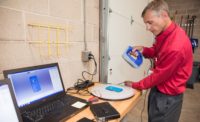

Services on display at the Cincinnati open house included 3D scanning, reverse engineering, quality inspection, instant scan-to-CAD comparison and a full suite of PolyWorks software solutions. Equipment shown at the event included Aicon 3D systems, Breuckmann 3D scanners, Leica Geosystems, Romer and Hexagon brands of scanning devices and related hardware, all of which were available for hands-on use by event attendees. Company representatives from the various equipment lines, as well as Exact Metrology’s team of application engineering and testing specialists, were present for demonstrations and technical presentations, throughout the event.

The EnvisionTEC line drew particular attention and Steve Young commented, “This new partner was a natural extension of our service work. We do 3D scanning and were using a 3D printer, so we had that light bulb moment and decided to connect with a 3D printer builder to expand our equipment offerings.”

Exact represents EnvisionTEC throughout the Midwest. EnvisionTEC is a Detroit-based builder of various 3D printers for the medical, dental, jewelry and various industrial sectors, offering machines to produce parts up to 18 inch cube.

As Steve Young further noted, “We constantly seek to find the optimum combination of equipment and services to suit the applications and challenges presented by our customers. In some cases, it’s a matter of matching the right standard equipment to the job, while at other times we bring custom solutions and services to our customers, whether they buy, lease or rent equipment or use our services to achieve the desired results on their metrology projects.”

Young credited his staff of metrology engineers, technicians and customer service personnel for their hard work, dedication and adaptability in seeking the correct solution to all customer challenges.

Exact serves both industrial and commercial concerns, ranging from heavy equipment, automotive and appliance companies to nuclear test facilities and even museums, who routinely use metrology to examine artwork such as paintings and sculpture.

Subsequently, Exact held an open house at its Brookfield, WI location.

Attended by 70 companies in the area, the event was hosted by Exact Metrology co-president Dean Solberg in conjunction with Exact partners EnvisionTEC, Hexagon Metrology, PolyWorks, 3DSystems and ETI.

A variety of scanning equipment was demonstrated throughout two rooms in the facility. One highlight of the open house was the new Leica BLK360 Imaging Laser Scanner, a 360-degree scanner that allows high resolution scans for a full-dome in less than three minutes. Other devices showcased included the Hexagon Metrology Romer Absolute Arm, several Artec3D scanners, the Surphaser 100HSX, several Leica long range scanners and the ProCon CT scanner. While demonstration pieces were available to scan, attendees were able to bring in their own parts to show live 3D scanning on the screen.

Also present at the open house was Exact Metrology’s new 3D printer partner, EnvisionTEC Inc. High-precision, high-detailed models illustrated the 3D printing capabilities of the Detroit-based manufacturer.

The Brookfield open house’s agenda consisted of four breakout sessions with experts in 3D metrology and scanning technology demonstrating their wealth of knowledge on the industry. The breakout sessions happened simultaneously during the day. During one presentation, Jason Reno of PolyWorks talked about what to expect in the industry for 2017. Another session was given by Dave Meyers, a professor affiliated with Effective Training Inc. He instructed the audience on the use of GD&T Training (Geometric Dimensioning and Tolerancing). Greg George, Corey Mayeda and Mike Tsand from 3DSystems gave a discussion on 3DSystems Software: DesignX and Geomagic.

For more information, visit www.exactmetrology.com.