Home » Keywords: » CT scanning

Items Tagged with 'CT scanning'

ARTICLES

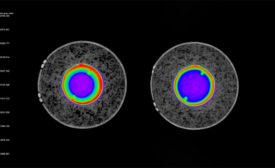

NDT | Computed Tomography

Industrial x-ray and CT inspection supports quality control and failure analysis at all stages of a battery's lifecycle.

Read More

NDT | Computed Tomography

Industrial CT: 3D Inspection and Metrology for 3D Printing

CT inspection of the final part can check that the manufactured part exactly matches the initial 3D design, providing dimensional analysis and metrology of all critical internal dimensions.

October 15, 2021

Computed Tomography: Back to Basics

Computed tomography is a powerful nondestructive evaluation (NDE) technique for both 2D and 3D cross-sectional images of an object from X-ray images.

July 1, 2020

Nondestructive Inspection of Automotive Computers

As with the testing and evaluation of raw materials, controlling the quality of electronic devices is essential

April 8, 2020

Introducing E-Mobility Inspection

Meet the quality inspection solutions for all components of E-Mobility: Battery, Power Electronics, E-Motor and Transmission.

January 2, 2020

Seeing is Believing: 2D and 3D X-ray Technologies for Nondestructive Testing

X-ray based techniques have many advantages for inspection and quality control.

November 1, 2019

NDT

Industrial CT Raises the Bar for Canyon Bicycles

Inspection with the use of industrial X-ray and computed tomography has helped Canyon Bicycles raise the bar on quality and safety.

October 1, 2019

NDT

4 Reasons Why CT is the Best Method for Medical Device Quality Inspection

CT is a huge benefit to the medical device industry and will only continue to grow.

October 1, 2019

Get our new eMagazine delivered to your inbox every month.

Stay in the know with Quality’s comprehensive coverage of the manufacturing and metrology industries.

SIGN UP TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing