Electrification continues to gain importance in our everyday lives. As a crucial technology for decarbonizing high-emission sectors like the automotive, transportation, energy, and heating for buildings, the climate goals and energy transition efforts of many countries depend on rising electrification. As a consequence, batteries have become omnipresent, and greater quantities still need to be produced. For battery manufacturers serving these recently electrified industries, scaling up production volumes while maintaining high quality is a huge challenge. Industrial X-ray and computed tomography (CT) inspection solutions address these challenges and can lead to major competitive advantages.

One of the most significant growth industries for battery manufacturers is the production of lithium-ion batteries for electric vehicles, or EVs, which literally drive the e-mobility sector. They are also one of its most complex components.

Lithium-ion batteries are among the most powerful energy storage devices commonly used in portable electronic devices, stationary power sources and electric vehicles. Manufacturers and suppliers are working hard to increase capacity, reducing charging times and extend lifecycles while remaining compliant with quality gates and safety standards. While the development and production process of lithium-ion batteries deployed in consumer electronic products has been honed to mass production capabilities, the product maturity of newer battery cells and packs developed for EVs is still years behind.

Scaling up their production without compromising safety or quality is therefore infinitely more challenging. In terms of research and development, lithium-ion cell technology is mature and has almost reached the end of its development. Batteries used in EVs today can have a storage capacity of up to 100 kWh, can be charged within 30 minutes and are created for up to 1,000 loading cycles throughout their lifetime – all while being remarkably robust.

The next hurdle for manufacturers is to achieve reliable and high-quality mass production of these cells to reduce costs. This is already working in laboratory settings, but there are several issues with regard to mass production. For example, manufacturers are working with chemicals from different suppliers, which can lead to flaws in the automated mass production of the cells.

Beyond making the current lithium-ion battery technology fit for mass production, the challenges manufacturers face are manifold. Pressure to extend the lifetime of EV batteries and safely increase energy efficiency while not impacting the weight of batteries, for example. Concurrently, they need to reduce scrap. At present, 15 to 30 percent of cells coming off production lines are still discarded due to flaws in manufacturing. A fast development cycle of new manufacturing technologies adds to this burden, as does the exponential growth in demand, which requires manufacturers to efficiently scale up to mass production, all while the necessary raw materials are becoming increasingly rare.

Modern Battery Cell Production For EVs

Regardless of type, lithium-ion batteries are all produced using complex processes in so-called gigafactories. This is where advanced industrial inspection by means of nondestructive testing (NDT) methods can notably contribute to improving factory productivity and the quality of all common cell types (cylindrical, prismatic and pouch) as well as battery packs and battery modules.

Industrial X-ray and CT inspection supports quality control and failure analysis at all stages of a battery’s lifecycle, from R&D to the failure analysis of defect batteries in production. Fast CT inspection also provides safe and secure at-line and in-line production control with reliable inspection of all vital parts. Additionally, it will play an important role in the scanning of end-of-life batteries to ensure their efficient reuse.

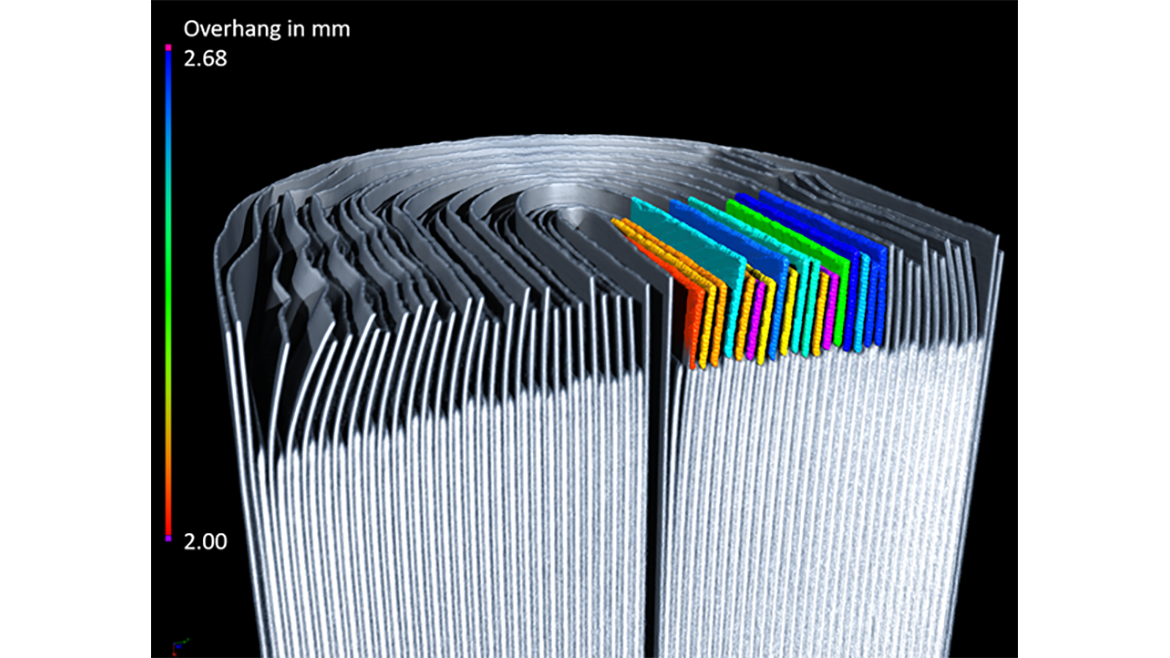

To maintain stable production processes, every produced cell can be scanned by CT inspection solutions for common fault patterns such as anode overhang. X-ray and CT technologies offer comprehensive quality inspections across all manufacturing levels while allowing manufacturers to check multiple failure cases concurrently. CT inspections are thus crucial for reducing scrap and guaranteeing a safe product and can be seamlessly integrated into the manufacturing process.

The anomalies that can be detected with CT inspection in battery components, battery cells and ESS (Energy Storage System) and EV modules are as manifold as the manufacturers’ challenges. Next to anode/cathode overhang inspection for pouch and prismatic cells, they include spot checks for items such as the inclusion of foreign body materials or gas bubbles and their exact position within the battery, welding defects of electrodes, electrode cracks, and electrolyte filling. CT inspection also allows manufacturers to detect tab defects like disconnect, folding and wearing areas to prevent overheating zones. With the prevalence of ever larger ESS & EV modules, the necessity to inspect complete modules for resin filling, connections, cell alignment, or dimensional accuracy also becomes increasingly important.

More Automation Enabling More Speed Equals More Batteries

To meet the market demand and scale up more quickly as well as to deal with a wide range of new technologies and processes, battery manufacturers are looking for ways to increase inspection automation. A key area for automation lies in finding defects automatically during inspections to gain speed and improve the quality of the inspected objects. Through comprehensive expertise in X-ray and CT inspection systems, the latest artificial intelligence (AI) machine learning (ML) software is able to find defects automatically and reliably for a variety of industrial sector components from castings to electronics and batteries.

The ADR (Automatic Defect Recognition) battery solution software is typically agnostic to battery cell types, having been adapted to cylindrical, prismatic, and pouch formats. It can be retrained and adjusted to fit the evolving nature and chemical setup of battery technology as next-generation batteries enter the market.

NDT

A Quality Special Section

It also covers different defects and features for analyzing battery issues. From checks of cathode and anode positionings and length to calculating the use of ML overhang exit angles for the highest cathode length neighbor relation and bending angles and spacing. Lastly, it determines if the electrode range is within adequate tolerances for high-performing battery demands. The volumetric registration running at the backend aligns CT volumes to support the machine learning in achieving high accuracy scores and thus producing excellent analysis results.

We also cooperate with specialized partners in the field of battery inspection. Among other things, this concerns digitally networked and highly automated production environments with the shortest cycle times as well as inspection requirements at the atomic level. In addition, official agreements exist with research institutions to help drive the ongoing development of batteries.

With these types of inspection, advanced industrial inspection becomes a key technology for the safe and efficient electrification of the mobility sector worldwide: It helps to reduce scrap and increase the output of battery cells which are subsequently delivered to EV manufacturers for final assembly - all the while maintaining the highest production quality possible.

Performance Inspections To Take Battery Technology To New Levels

Industrial X-ray and CT can accompany many critical steps within the production process of modern EV batteries. In so doing, it plays a vital part in making the future of mobility more sustainable.

Solutions are available to help solve any inspection challenge that battery manufacturers may encounter along the way. With CT systems for micro- and nanofocus inspections as well as at-line and in-line CT scanners, NDT providers can help manufacturers scale up production safely and efficiently – so they can help automotive OEMs decarbonize quickly and sustainably.