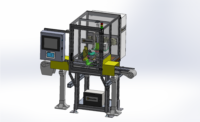

Optical fiber manufacturers can quickly assess the geometry of their product with a new high speed automated measuring system from Arden Photonics. Designed for production and R&D environments, the FGC-G range delivers repeatable, operator-independent results in less than 10 seconds.

The comprehensive measurement capability for end-face geometries includes core diameter, core non-circularity, cladding diameter, cladding non-circularity and core-to-cladding concentricity. Designed for both specialty and telecoms fibers, the units have the latest software that makes it possible to measure even multicore fibers automatically.

Two models are available, with the FGC-GT optimized for 125 um diameter fibers but also able to measure up to 400 um. Typical applications are the development and manufacture of single and multimode telecom fibers, although specialty fibers can also be measured.

The FGC-GS can measure fibers up to 1 mm in diameter, and is optimized for specialty fibers such as octagonal and dual-cladding types.

For cladding diameter and non-circularity measurements the units operate in reflection mode. The use of clear end-face illumination provides precise, automatic focusing so that defects on the fiber circumference can be detected and eliminated from the fit, giving greater measurement accuracy.

Transmission mode is used for core diameter and non-circularity measurements, with illumination provided by an array of nine LEDs, giving fully filled launch over a wide range of fiber types.

The research friendly, flexible software offers a templates system that can be customized to allow the user to specify the type of fiber to be measured.

A further benefit of the FGC-G is that being able to measure the widest range of fiber types and sizes means that only a single unit is needed, reducing both bench space and the necessary training.

Arden Photonics

+44 (0) 121 733 7721