As technology has marched forward, advanced manufacturing organizations have wrestled with how to fill jobs with competent workers. The road toward the smart factory is paved with data-driven processes, automation and continuous improvement enabled by measurement, sensing, process control and next-generation communications. This new paradigm requires a labor force of skillful metrologists and manufacturing specialists. Fullerton College of Fullerton, CA, intends to be a player in preparing students for a dynamic future and jobs that harness manufacturing intelligence to optimize production operations.

Expert-level Machinists = Expert-level Metrologists

Located in Southern California, Fullerton Community College is responding to industry needs from local manufacturing companies to help fill in-demand employment positions. The college is one of California’s leading institutions for career technical education. Starting in the fall of 2018, the college is offering a new metrology (the science of measurement) program that has been in the works for the past several years. The Machine Technology department has been awarded several grants to acquire the necessary technology for the program. Funded by the Carl Perkins Act and the more recent California Strong Workforce Initiative, this new program is part of the college’s ongoing pursuits to educate students for careers in emerging fields. In order to be an expert level machinist, students have been taught that they also need to be expert-level metrologists. The addition of a metrology program certificate fits well with Fullerton’s advanced manufacturing / machining program educational philosophy.

A shop floor-ready machinist must have the expertise to accurately measure parts so proper adjustments can be made to machine setups and CNC controls. This critical skill set makes it possible for parts to be manufactured to engineering drawings and part specifications. The new metrology program not only allows machine shop students to achieve additional certifications, but also allows them to pursue a career in the field of metrology.

Industry Demand Grows for Digital Measurement Technologies

Advanced manufacturing companies across the country are employing new automated measuring tools to meet industry demands for 3D Model-based Definition Part Inspection. These new technologies require a workforce that is familiar with traditional measuring methods, along with new digital measurement solutions. The Orange County area in Southern California is home to numerous high tech companies producing precision components for the medical, aerospace and commercial industries. The growing usage of digital measurement technology has created a demand for a workforce that is well versed in these methods.

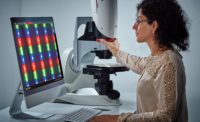

The new metrology program fits well with Fullerton’s advanced manufacturing / machining program educational philosophy. Photo credit: Elizabeth Reyes

The challenge for the industry lies in the pipeline of entry level manufacturing workers. Currently, there is a shortage of workers, and there are not enough qualified professionals to fill positions being vacated by retiring workforce. According to the Orange County Workforce Indicators Report (2016) in Orange County alone, there are 100,000 advanced manufacturing jobs. Many of these jobs require advanced manufacturing skills that are not readily obtainable. Over the next ten years, the demands for employees in the area of advanced manufacturing will only continue to grow.

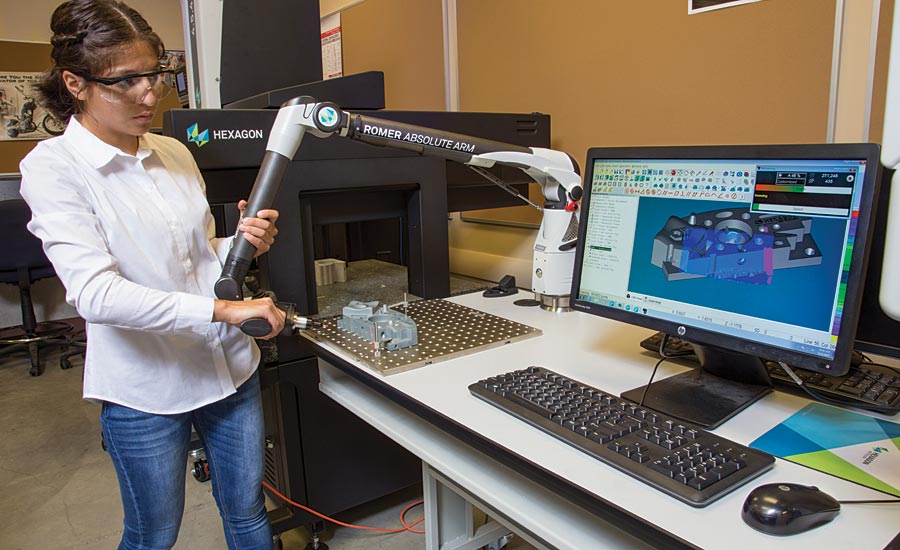

The Fullerton College certificate program is developed to deliver a hands-on understanding of metrology and a thorough knowledge of laboratory techniques using the equipment. Photo credit: Elizabeth Reyes

Filling the Gap with Technology Training

Fullerton Community College intends to fill the employment gap by offering a metrology program that includes programs that enable students to earn up to two certificates. Students completing the twenty nine unit program will be awarded a certificate of achievement, which is documented on college transcripts. This program includes fundamental courses in manufacturing that are applicable for people currently working in manufacturing related careers along with students who are seeking entry-level employment in the field. An eleven-unit skills certificate includes metrology, PC-DMIS software, ROMER Absolute Arms and coordinate measuring machine operation and programming. This certificate is intended for people already employed in related fields who seek training opportunities with new technologies. This set of courses will enhance existing programs in the technology and engineering division by offering one of the only community college level metrology programs in California.

The introductory-level metrology curriculum will emphasize the theory and proper use of dimensional equipment, the collection/statistical treatment of 3D data, blueprint reading and other electronic computer-aided metrology equipment. The intent of the certificate program is to deliver a hands-on understanding of metrology along with a thorough knowledge of laboratory techniques in using the equipment.

The college has partnered with Hexagon Manufacturing Intelligence (North Kingstown, RI) to offer courses utilizing PC-DMIS measurement software that is used to collect, evaluate, manage and present measurement data for manufacturing and scientific applications. PC-DMIS software is widely used in the Southern California area. This new program introduces the first college-level training opportunity in the area, outside of end user training offered at Hexagon Solution Centers. Measurement technologies such as Hexagon coordinate measuring machines (CMMs) and twelve ROMER Absolute Arms equipped with laser scanners will be utilized for hands-on practical learning.

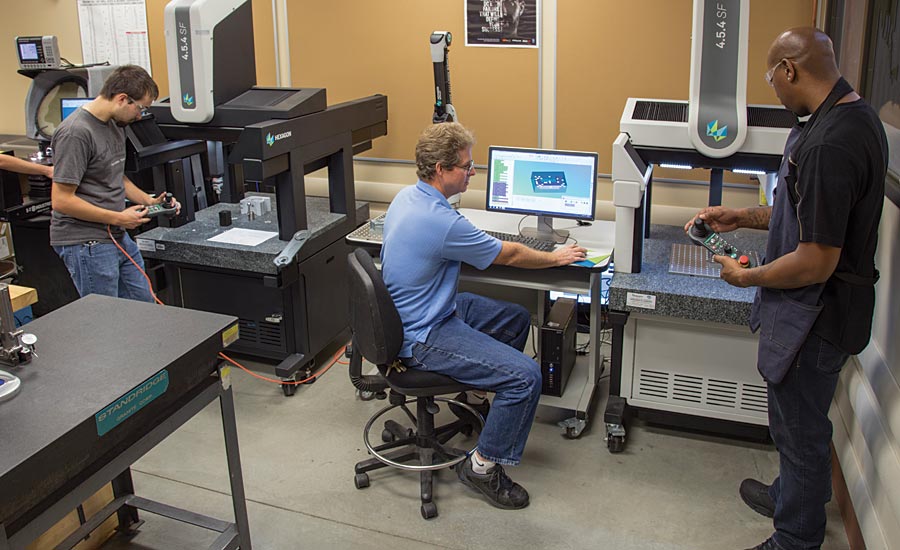

Students will learn how to create inspection plans using PC-DMIS and develop inspection reports in line with industry standards. Photo credit: Elizabeth Reyes

In addition, Hexagon University curriculum will be utilized for course exercises along with measurement training that will have students inspecting a series of parts that seem identical but will have dimensional flaws that they must discover, too. Students will be required to develop and implement inspection plans, procedures and complete inspection reports that comply with ISO and

AS requirements.

From Skills Certificates to A.S. Degrees

The manufacturing program at Fullerton College already has a strong offering of courses such as blueprint reading, geometric dimensioning & tolerancing (GD&T), CAD/CAM, metallurgy, and manufacturing processes that were utilized as part of the certificate program. These courses are currently available. New courses include a general metrology course and three courses utilizing PC-DMIS software used as the interface to CMMs and portable ROMER articulating arms. There is also an applications course teaching students how to create inspection plans and develop inspection reports that are in line with industry standards. The completion of this certificate prepares the student for a career as an inspector or quality control technician. The strategic combination of training in machining, CNC programming, and the inspection certificate will yield highly desired graduates for small manufacturing companies where employees must wear many hats in their daily duties.

Students can enroll at the college to earn the eleven unit skills certificate or twenty nine unit certificate of achievement in the field of metrology. Students can also further their education by pursuing an Associate in Science (A.S.) degree in manufacturing technology, and focus on a career in line with their chosen occupational field such as machining, drafting, welding, printing, construction, technology areas, and now metrology. An additional thirty one units of coursework in general education areas, in addition to the metrology certificate, are required to satisfy the A.S. degree requirements.

Technical Education Opens Career Doors

California’s Community College system is one of the best in the United States, and it provides an economical alternative for the first two years of general studies, as compared to four-year universities. Many students spend their first two years taking lower division courses at a community college before transferring to four year schools. One of the advantages of attending a community college is that students will get exposed to career paths that will ultimately guide them to lucrative employment positions once they graduate.

Career technical education is offered at most California community colleges. These CTE programs allow students to explore different career paths so they can find a pursuit that suits them best. Many of these programs utilize state-of-the-art advanced equipment to provide training for in-demand job skills. In many cases, students enroll in technical courses just to learn a new technology that is required for their employment. These studies can lead to students continuing their education to earn various certificates, A.S. degrees and even transfer to four year engineering programs.

New curriculum for all metrology and machine technology courses will allow course work to transfer to four year universities starting in the fall of 2018. Upon completion of studies at Fullerton College, students can continue their educational pursuits with advanced studies in engineering programs in the areas of manufacturing, quality and mechanical engineering.

For more information on Hexagon, contact Bridget Benedetti, director of marketing and communications, Hexagon Manufacturing Intelligence, at (401) 248-5324, email [email protected] or visit www.HexagonMI.com.