Like most new things, producing a new product comes with new challenges. Automotive manufacturers competing in today’s electric vehicle (EV) industry are facing challenges with one of the newest components of the modern EV— the battery tray.

Responsible for containing the battery cells, connectors, control units, and battery packs, including various battery modules, this complex aluminum weld design has a direct bearing on the functionality, performance, and safety of the EV. For example, the battery cells contained within a battery tray save high amounts of energy, and thermal expansion of these cells can lead to torsion and cause the battery tray and complete car body to bend if the two components are not adequately integrated.

Ensuring the battery tray is secured to the car and mechanically stable requires the validation of specific critical geometries and tolerances. The connection points that attach it to the car body must be the correct size and location. However, the location of a hole, slot, or flange can change during the welding process due to the spring back of sheet metal. With battery tray inspection typically including a few select features, these small but critical changes to connection points are sometimes discovered later when the part suddenly does not fit during assembly. This lack of information about the complete part creates blind spots that contribute to scrap and downtime to perform root cause analysis and determine corrective action when problems are discovered within an assembly process that should otherwise be fully automated. So, how can EV manufacturers quickly gain access to more information about the battery tray to predict, prevent, and respond to issues as they arise before they go further down the production line?

Automating Inspection to Increase Throughput and Capture More Information Faster

Noncontact automated blue light 3D scanning offers EV manufacturers a faster way to capture more data during an inspection by digitizing the entire surface of the battery tray. Not only does this provide a geometric digital twin that delivers deeper insight into what is happening with the part, but automating the inspection process also optimizes inspection time, increases measuring capacity, and improves the analysis and reaction time of necessary process changes.

Performing automated inspection with this method is simple: after the battery tray is loaded and secured into the automated 3D scanning inspection cell, the blue light 3D scanning sensor, mounted onto a robotic arm, moves around the battery tray, collecting millions of accurate XYZ data points per scan. Single scans are combined reliably using reference points and surface matching within advanced 3D metrology software. Common reference points on the battery tray allow both sides of the tray to be scanned and aligned for a complete digital twin of the battery tray that is useful for comprehensive data analysis and further enables the advantages of digitalization.

Increasing Throughput with Digitalization

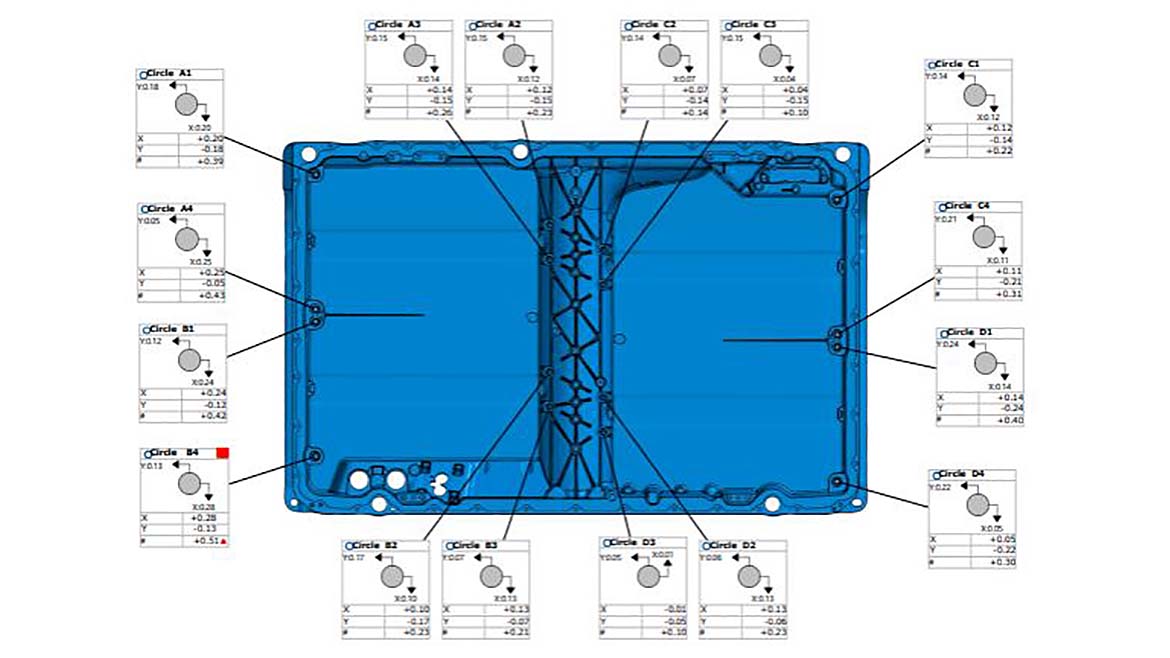

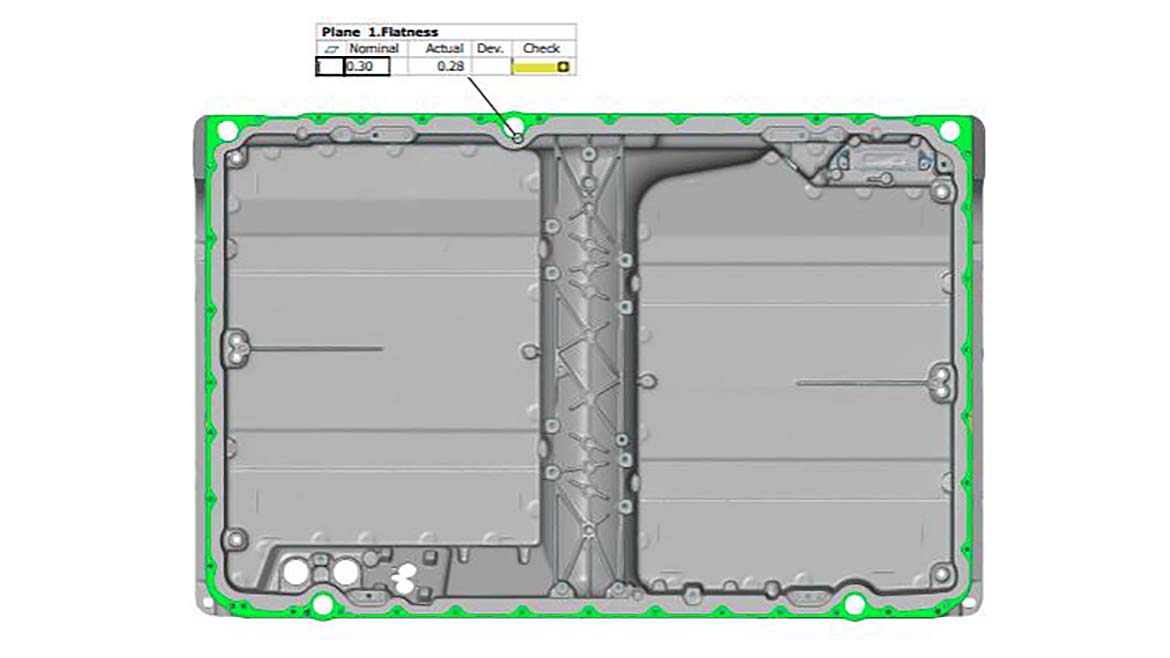

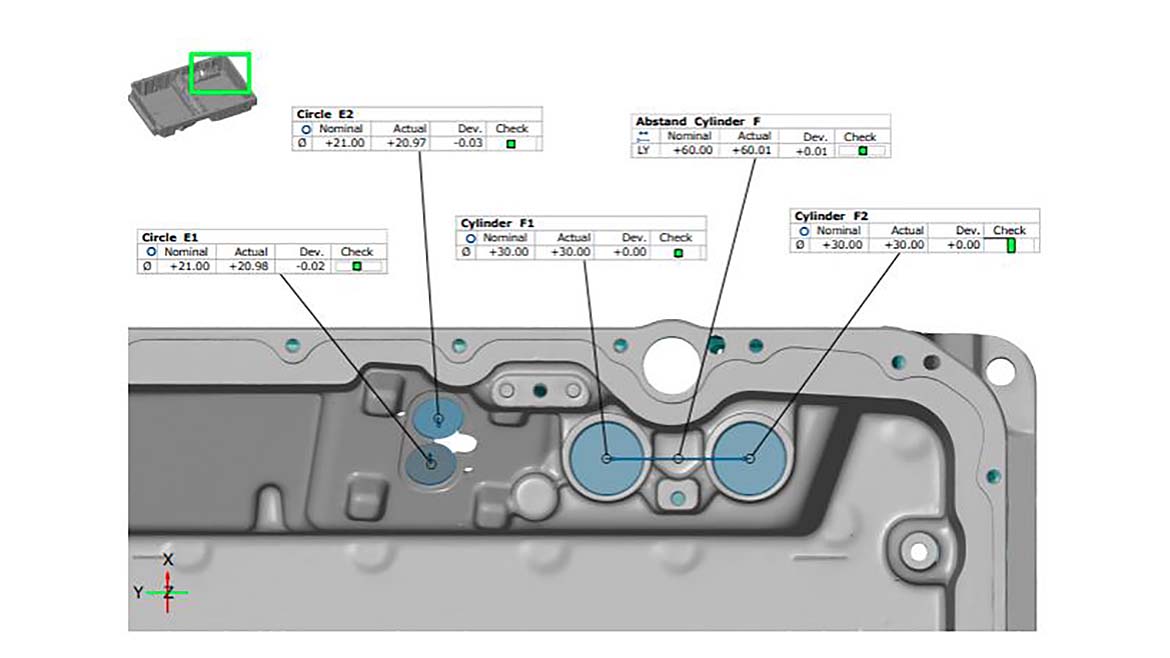

Adequate securing of the battery tray helps to ensure its ability to handle load forces during driving, charging, and in the event of an accident, making validation of the size and location of the welded connection points critical to fit and finish. Inspecting the connection holes is faster and more effective by analyzing an accurate digital twin of the part inside 3D metrology software. Within a few clicks, the software inspects the position of the connection holes, applying geometric dimensioning and tolerancing (GD&T) checks to quickly and visually reveal deviations in shape, such as flatness, or changes in position.

Flatness inspection of the mating and sliding surfaces is also essential for properly integrating the tray into the car body. GD&T functions within 3D metrology software can calculate the flatness or surface profile of sealing surfaces or individual battery compartments, including the height and position of the sealing bead.

Accurate Data Predicts Quality Issues Before They Happen

Since the battery tray component is among the newer parts powering the modern EV, the optimal process for inspecting, producing, and assembling the component is still developing. As a result, having the flexibility to make process changes easily is an advantage. With complete surface data, manufacturers can perform additional measurements and analyses at any point without measuring the part again, allowing the flexibility to redefine new measurement criteria and apply these changes to the process moving forward.

Digitalization of the battery tray also helps manufacturers understand the performance of a new or current process. By analyzing data trends to identify changes in the production process at an early stage, manufacturers have the opportunity to get ahead of issues before they occur. For example, executing trend analysis on process-related inspection features like the location of the fixing holes allows for a series inspection of the feature by analyzing several holes at once to show when in the process the location changed. Observing these changes over time helps manufacturers predict when features may fall out of tolerance and prevent issues before they happen. The software saves the digitized part, making it available to refer back to and help guide root cause analysis for a faster resolution if issues are unexpectedly discovered at a later stage.

Digital Assembly Improves Efficiency

Digital assembly, a digital twin application driven by 3D measurement data, enables EV manufacturers to simulate, predict, optimize, and verify the assembly and fit of the battery tray and related components before it is assembled physically. Using scan data from the physical parts, EV manufacturers can evaluate the interaction of the battery modules within the battery tray, simulate and optimize various assembly situations with different local alignments, and use the surface deviations between the battery module and the battery tray to calculate the volume of the required heat-conducting paste for the individual battery compartments. With this method, manufacturers save time and gain confidence, knowing the physical parts can move to the next stage.

Many EV manufacturers are still searching for the optimal inspection method for the battery tray. However, to maximize the time spent on inspection, using an automated 3D scanning solution is the key to increasing speed and improving their overall process with digitalization. Discovering the challenges that come with producing a new product and understanding how to overcome them requires information. In this learning phase, there’s no such thing as too much information— but the speed of information matters.