Home » cameras

Articles Tagged with ''cameras''

New Product

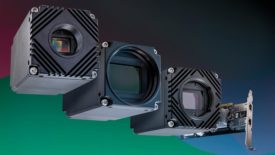

IDS Industrial Camera Offer Sony Sensor IMX662 in Both Color and Mono

March 26, 2024

Vision & Sensors | Lenses

Understanding the Key Factors in Microscope Objective Performance

February 6, 2024

New Product

Emergent Vision Technologies Plug-ins for eCapture Pro Software

February 5, 2024

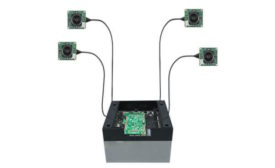

Vision & Sensors | Camera Interfaces

RDMA with 10GigE Cameras

High-speed, Maximum Reliability

February 2, 2024

Vision & Sensors | Lighting

Liquid Lenses and Cameras: Unmatched Control over Optical Parameters

Learn more about liquid lens technology.

December 28, 2023

Get our new eMagazine delivered to your inbox every month.

Stay in the know with Quality’s comprehensive coverage of the manufacturing and metrology industries.

SIGN UP TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing