Home » Keywords: » color management

Items Tagged with 'color management'

ARTICLES

Quality 101

True Colors

Read More

Measurement

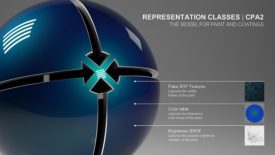

Why Digital Workflows Require More Than Digital Color

If you only digitize color using spectral data, you are missing valuable data required for the digital design and visualization workflow.

December 29, 2023

Measurement

The Art and Science of Digital Color

Precise color management is essential to consumer perceptions of product value.

December 20, 2023

Color Measurement

Is Your Color Workflow Resilient for Today’s Supply Challenges?

Capturing and analyzing color data can help identify areas for improvement.

October 1, 2022

Test & Inspection

Shining A Light On Color Quality Control

Monitoring color during the entire production process can help manufacturers identify color drifts before they become a problem.

March 8, 2022

Getting Color Right (It's Trickier Than It Sounds)

What you need to know for effective color management.

January 6, 2021

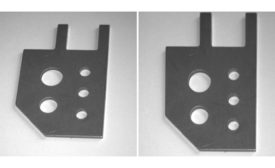

Several Common Image Analysis Software Tools in Machine Vision

There are many different ways that an image can be distorted.

September 1, 2020

Color Management 101: The Latest Technology and Techniques

Whether you are first introducing color control to your quality process or you are managing an existing framework, here’s what to know.

April 1, 2020

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing