Home » Keywords: » manufacturing technology

Items Tagged with 'manufacturing technology'

ARTICLES

Software

Short run charts work for both variable and attribute data.

Read More

Software & Analysis

How modern software can transform the supply chain with manufacturing quality at the center

Enable a manufacturing quality-driven collaboration between suppliers and buyers to eliminate interpretation, reduce costs, risks, and expedited delivery time.

February 16, 2024

NDT | Additive

A Window of Opportunity to Accelerate Alloy Development for Additive Manufacturing

Opportunities for the development and validation of new tools, techniques, and methods to accelerate alloy development for AM processes do exist.

August 14, 2023

Vision & Sensors | Lighting

Creative Illumination Techniques Enable Computational Imaging

Computational imaging can simplify certain problems that are difficult to solve with standard visual imaging.

January 2, 2023

Measurement

Best Suited Options for Your Metrology Toolbox

When are non-contact structured light 3D scanners better suited than touch CMMs?

September 8, 2022

5 Signs You May Need A Cloud-Based Quality Software Solution

Cloud based quality software has numerous benefits for manufacturers with disparate production facilities and locations.

August 8, 2022

Vision & Sensors | Cameras

AI Vision Development for Everyone

The time it takes moving from a concept to a running application can be greatly reduced.

July 4, 2022

Vision & Sensors

Vision & Sensors 101: Machine Vision System Integration

Success with vision system integration requires starting right.

January 1, 2022

Software & Analysis

Practical Reverse Engineering

Choosing the right tools for the job.

December 6, 2021

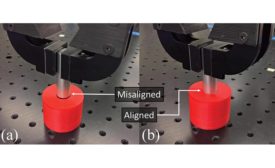

Helping Robots Stay on Target

Both accuracy and repeatability are key performance characteristics that influence the robot's ability to meet a manufacturing process's needs.

December 2, 2019

EVENTS

Webinar

10/18/23 to 10/18/24

Contact: Meg K.

Cut Training Time and Improve Quality With Interactive Digital Work Instructions

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing